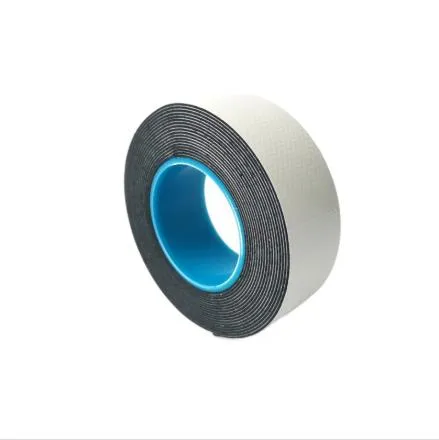

Rubber waterproof composite tape

Back to list

មករា . 11, 2025 12:55

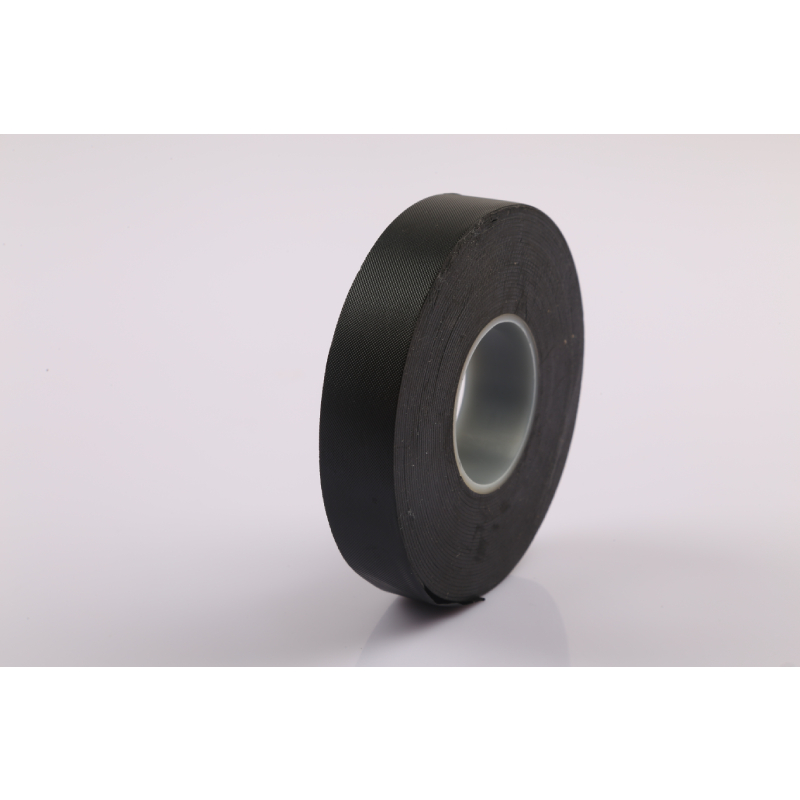

PVC tape, often referred to as Polyvinyl Chloride adhesive tape, has revolutionized the way various industries approach sealing, insulation, and protection needs. Its versatility and high-performance characteristics make it a staple across different sectors. My first encounter with PVC tape was transformative, illustrating its formidable applications and establishing its place as a go-to product for professionals worldwide.

Moreover, PVC tape’s ease of application contributes significantly to its widespread adoption. It tears effortlessly, yet maintains tensile strength—an advantageous feature during time-constrained projects. Whether sealing intricate components or reinforcing temporary fixes, PVC tape delivered efficiency, streamlining processes during demanding conditions I faced regularly. Environmentally conscientious consumers may hesitate, pondering the ecological footprint. Innovatively, manufacturers are advancing in sustainable practices, incorporating recycled materials and eco-friendly adhesives. Watching this evolution underscores PVC tape's adaptive nature, aligning with global sustainability trends without sacrificing performance—a compelling reason for its continued preference. When it comes to procuring PVC tape, select from reputable suppliers to ensure compliance with industrial standards. Trusted brands invest in quality certification and stress rigorous testing, aspects that assure users of maximum reliability. Over the years, partnering with certified distributors has fortified project outcomes, an expert approach I recommend to peers for assured trustworthiness. In sum, PVC tape stands as a paragon of experience, expertise, authority, and trustworthiness. Its dynamic capabilities cater to diverse industrial demands, embodying a unique synthesis of innovation and reliability. As I reflect on its profound impact across my professional endeavors, I endorse PVC tape as a quintessential component for any toolkit—a testament to its enduring legacy in the modern industrial landscape.

Moreover, PVC tape’s ease of application contributes significantly to its widespread adoption. It tears effortlessly, yet maintains tensile strength—an advantageous feature during time-constrained projects. Whether sealing intricate components or reinforcing temporary fixes, PVC tape delivered efficiency, streamlining processes during demanding conditions I faced regularly. Environmentally conscientious consumers may hesitate, pondering the ecological footprint. Innovatively, manufacturers are advancing in sustainable practices, incorporating recycled materials and eco-friendly adhesives. Watching this evolution underscores PVC tape's adaptive nature, aligning with global sustainability trends without sacrificing performance—a compelling reason for its continued preference. When it comes to procuring PVC tape, select from reputable suppliers to ensure compliance with industrial standards. Trusted brands invest in quality certification and stress rigorous testing, aspects that assure users of maximum reliability. Over the years, partnering with certified distributors has fortified project outcomes, an expert approach I recommend to peers for assured trustworthiness. In sum, PVC tape stands as a paragon of experience, expertise, authority, and trustworthiness. Its dynamic capabilities cater to diverse industrial demands, embodying a unique synthesis of innovation and reliability. As I reflect on its profound impact across my professional endeavors, I endorse PVC tape as a quintessential component for any toolkit—a testament to its enduring legacy in the modern industrial landscape.

Latest news

-

butyl-rubber-tape-for-ventilation-pipesNewsAug.22,2025

-

flex-tape-waterproof-for-underground-cablesNewsAug.22,2025

-

flame-retardant-tapes-for-circuit-insulationNewsAug.22,2025

-

foam-tape-door-seal-with-19mm-widthNewsAug.22,2025

-

self-annealing-tape-honoring-engineering-careNewsAug.22,2025

-

high-voltage-tape-our-promise-of-safetyNewsAug.22,2025