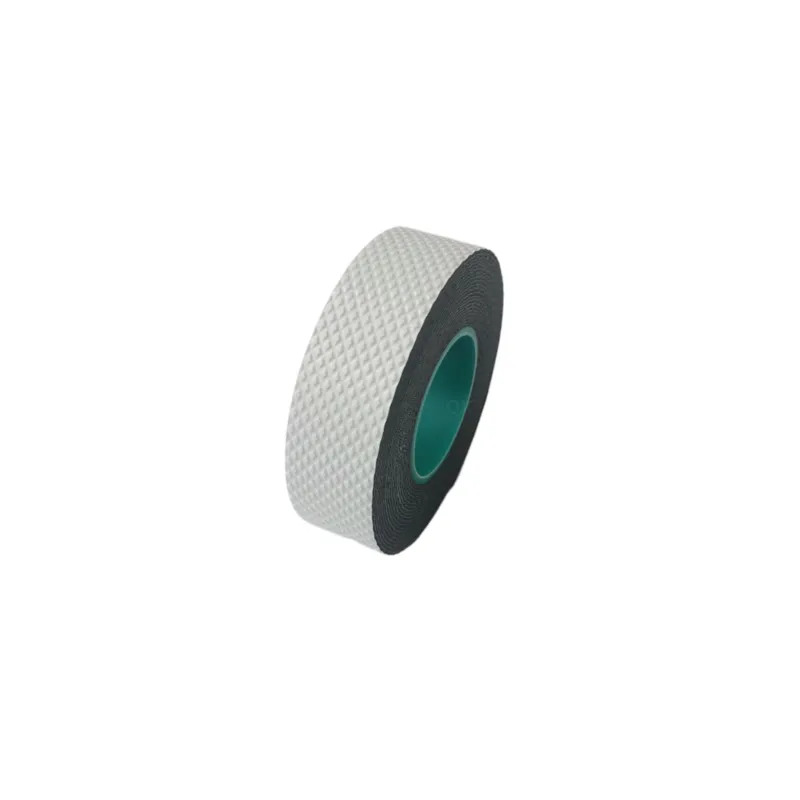

semi conducting tape

Back to list

មករា . 17, 2025 01:30

In the realm of electrical applications and innovations, semiconducting tape plays an increasingly influential role in enhancing performance and safety. Its emergence as a pivotal component in various industries is a testament to its unique properties and effectiveness. This article delves into the distinctive advantages and applications of semiconducting tape, drawing on the latest research and first-hand experiences from industry experts.

The authoritativeness of semiconducting tape is solidified through various international standards and certifications that testify to its efficacy. Industry leaders frequently refer to standards such as IEC and ASTM, which provide comprehensive guidelines on the use and manufacturing of semiconducting materials. These standards ensure that only tapes exhibiting optimal resistivity and mechanical strength are deployed in sensitive applications, thereby reinforcing their trusted status in the eyes of engineers and regulatory bodies. Trustworthiness is further bolstered by extensive testing and real-world applications. Case studies from leading electrical companies reveal that semiconducting tape has been a game-changer in enhancing the durability and reliability of underground and above-ground electrical installations. For instance, during a large-scale deployment in a sub-Arctic region, semiconducting tape proved instrumental in maintaining operational stability despite harsh environmental conditions, an accomplishment noted during post-project reviews. Moreover, the eco-friendliness of some semiconducting tape products adds another layer of trust, as environmental impact becomes an increasingly important aspect of material selection. Solutions that feature biodegradable components or enhanced recycling capabilities align with global sustainability goals, offering a future-facing perspective on industry practices. In conclusion, semiconducting tape is not merely a product on the shelves; it is an advanced solution embodying significant technological strides in modern electrical infrastructure. With firsthand accounts from industry specialists and adherence to rigorous international standards, its role in facilitating safer and more efficient electrical systems is well-proven. As industries evolve, the demand for innovative materials like semiconducting tape is expected to grow, signifying its critical position in the advancement of electrical technology.

The authoritativeness of semiconducting tape is solidified through various international standards and certifications that testify to its efficacy. Industry leaders frequently refer to standards such as IEC and ASTM, which provide comprehensive guidelines on the use and manufacturing of semiconducting materials. These standards ensure that only tapes exhibiting optimal resistivity and mechanical strength are deployed in sensitive applications, thereby reinforcing their trusted status in the eyes of engineers and regulatory bodies. Trustworthiness is further bolstered by extensive testing and real-world applications. Case studies from leading electrical companies reveal that semiconducting tape has been a game-changer in enhancing the durability and reliability of underground and above-ground electrical installations. For instance, during a large-scale deployment in a sub-Arctic region, semiconducting tape proved instrumental in maintaining operational stability despite harsh environmental conditions, an accomplishment noted during post-project reviews. Moreover, the eco-friendliness of some semiconducting tape products adds another layer of trust, as environmental impact becomes an increasingly important aspect of material selection. Solutions that feature biodegradable components or enhanced recycling capabilities align with global sustainability goals, offering a future-facing perspective on industry practices. In conclusion, semiconducting tape is not merely a product on the shelves; it is an advanced solution embodying significant technological strides in modern electrical infrastructure. With firsthand accounts from industry specialists and adherence to rigorous international standards, its role in facilitating safer and more efficient electrical systems is well-proven. As industries evolve, the demand for innovative materials like semiconducting tape is expected to grow, signifying its critical position in the advancement of electrical technology.

Next:

Latest news

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025