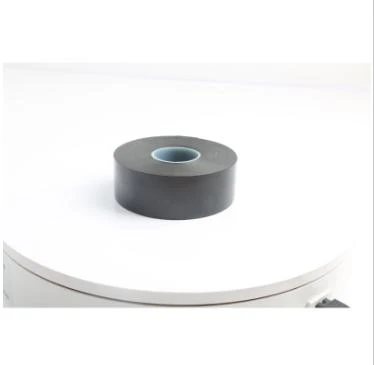

automotive wiring harness tape

Back to list

Feb . 03, 2025 03:59

The automotive wiring harness wrap stands as an essential component within the automotive industry, influencing both the performance and longevity of vehicles. As vehicles become increasingly complex, the need for effective wiring management solutions has never been greater. This product plays a pivotal role in safeguarding vehicle electrical systems, ensuring reliability and efficiency. The expertise involved in selecting the right wiring harness wrap can significantly impact vehicle performance, and as such, it is essential to delve deeper into its benefits and applications.

In terms of authoritativeness, automotive wiring harness wraps are continuously evolving with technological advancements in the automotive sector. As smart cars and electric vehicles gain traction, the demand for robust wiring solutions is escalating. Leading manufacturers invest heavily in research and development to innovate and improve the efficacy of these wraps, thereby maintaining their competitive edge. Such companies often contribute to industry standards and guidelines, showcasing their authority in the market. Trustworthiness in automotive wiring harness wraps comes from rigorous testing and adherence to international quality standards. Before reaching the market, these products undergo comprehensive testing to ensure they meet the high-performance demands of modern vehicles. Certifications from reputable organizations offer consumers assurance about the product's reliability and safety, making it a trusted choice for vehicle manufacturers and repair services alike. Moreover, real-world application stories underscore their trustworthiness. Automotive electrical systems, with top-tier wiring harness wraps, have exhibited exceptional performance in various environmental conditions—from extreme cold to high heat and humidity. This longevity and resilience enhance consumer confidence in the product, encouraging its widespread adoption. In conclusion, the automotive wiring harness wrap is more than just a protective covering for wires; it is a critical component that significantly impacts vehicle reliability and safety. By combining experience-based insights, expert material selections, authoritative innovations, and trusted performance metrics, automotive professionals can ensure these accessories genuinely optimize vehicle electrical systems. The development and application of automotive wiring harness wraps are a testament to the relentless pursuit of excellence in the automotive industry, reflecting the balance of state-of-the-art technology and user-centric design.

In terms of authoritativeness, automotive wiring harness wraps are continuously evolving with technological advancements in the automotive sector. As smart cars and electric vehicles gain traction, the demand for robust wiring solutions is escalating. Leading manufacturers invest heavily in research and development to innovate and improve the efficacy of these wraps, thereby maintaining their competitive edge. Such companies often contribute to industry standards and guidelines, showcasing their authority in the market. Trustworthiness in automotive wiring harness wraps comes from rigorous testing and adherence to international quality standards. Before reaching the market, these products undergo comprehensive testing to ensure they meet the high-performance demands of modern vehicles. Certifications from reputable organizations offer consumers assurance about the product's reliability and safety, making it a trusted choice for vehicle manufacturers and repair services alike. Moreover, real-world application stories underscore their trustworthiness. Automotive electrical systems, with top-tier wiring harness wraps, have exhibited exceptional performance in various environmental conditions—from extreme cold to high heat and humidity. This longevity and resilience enhance consumer confidence in the product, encouraging its widespread adoption. In conclusion, the automotive wiring harness wrap is more than just a protective covering for wires; it is a critical component that significantly impacts vehicle reliability and safety. By combining experience-based insights, expert material selections, authoritative innovations, and trusted performance metrics, automotive professionals can ensure these accessories genuinely optimize vehicle electrical systems. The development and application of automotive wiring harness wraps are a testament to the relentless pursuit of excellence in the automotive industry, reflecting the balance of state-of-the-art technology and user-centric design.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025