Exploring the critical role of high-performance wire harness tapes in modern vehicle electrical systems

JULU COUNTRY XIANGFAN SEALS FACTORY

As a leader in automotive sealing solutions, we provide cutting-edge wire harness tapes with superior technical specifications and reliability.

Industry Trends & Market Overview

The automotive industry continues its rapid evolution toward electrification, with Automotive Wire Harness PVC Tape becoming increasingly critical in vehicle manufacturing. According to industry analyses, the global automotive tapes market is projected to grow at a 6.7% CAGR between 2023 and 2030, driven by expanding EV production and complex electrical systems in modern vehicles.

Manufacturers like JULU COUNTRY XIANGFAN SEALS FACTORY have responded to these demands with advanced Automotive Wire Harness PVC Tape featuring enhanced thermal stability, greater adhesion strength, and improved chemical resistance. The XF-110 series represents the cutting edge in this category, providing superior protection in high-temperature engine compartments and extreme conditions.

Product Spotlight: PVC Tape for Modern Vehicles

The Automotive Wire Harness PVC Tape offered by JULU COUNTRY XIANGFAN SEALS FACTORY features:

- Manufactured with premium PVC film using DOP as the primary plasticizer

- High-performance pressure-sensitive adhesive formulation

- Superior insulation properties meeting automotive safety standards

- Exceptional cold resistance (down to -40°C)

- Voltage resistance exceeding industry requirements

- ROHS-compliant environmental standards

- Available models: XF-11, XF-13, XF-15, XF-18, XF-110

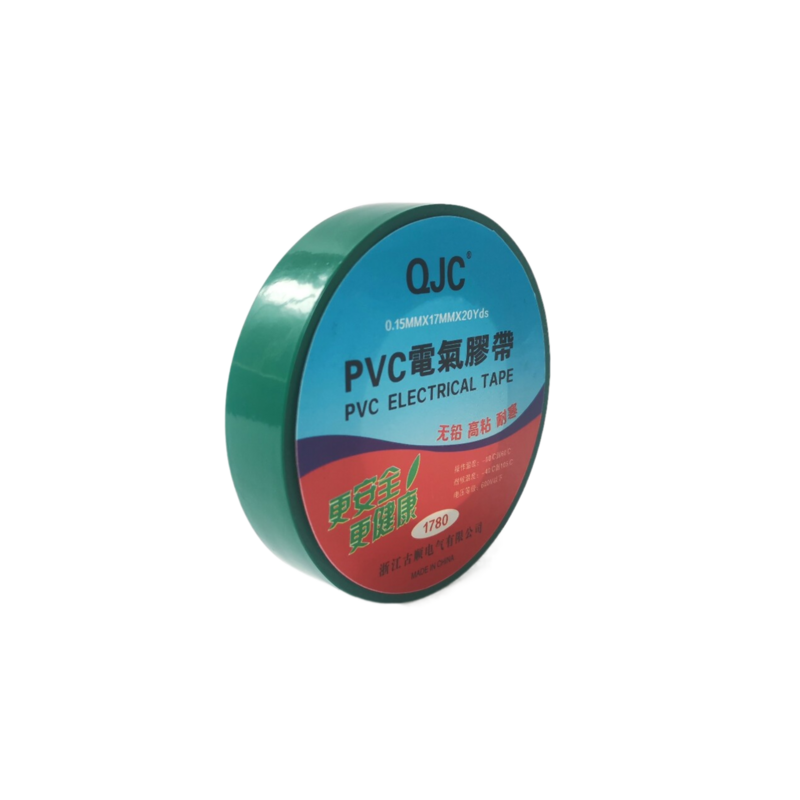

- Color options: Black, Red, White, Green, Blue, Yellow, Grey

Technical Parameters & Performance Data

| Parameter | XF-11 | XF-13 | XF-15 | XF-18 | XF-110 |

|---|---|---|---|---|---|

| Thickness (mm) | 0.12 ± 0.02 | 0.13 ± 0.02 | 0.15 ± 0.02 | 0.18 ± 0.02 | 0.16 ± 0.02 |

| Tensile Strength (N/cm) | 25 | 30 | 32 | 35 | 38 |

| Elongation at Break (%) | 220 | 230 | 240 | 250 | 260 |

| Adhesion to Steel (N/25mm) | 12.0 | 14.0 | 15.5 | 16.0 | 18.5 |

| Temperature Range (°C) | -30 to +105 | -35 to +110 | -35 to +115 | -40 to +120 | -40 to +130 |

| Voltage Resistance (kV/mm) | 8.0 | 8.5 | 9.0 | 9.5 | 10.0 |

Performance Comparison

Temperature Stability Analysis

Application Scenarios

The versatile Automotive Wire Harness PVC Tape finds critical applications throughout modern vehicles:

1. Engine Compartment Wiring

The XF-110 series excels in high-temperature environments near engines, providing critical protection against heat degradation and oil exposure. Proper Automotive Wire Harness PVC Tape application here prevents electrical shorts that could lead to catastrophic system failures.

2. EV Battery Systems

Electric vehicles demand specialized protection for high-voltage battery connections. JULU COUNTRY XIANGFAN SEALS FACTORY's Automotive Wire Harness PVC Tape provides dielectric insulation exceeding 600V, while its flame-retardant properties enhance safety in case of thermal runaway events.

3. Chassis and Underbody Applications

Manufacturers utilize the XF-18 variant with its superior moisture barrier properties to protect wiring from road debris, saltwater, and mechanical abrasion in vehicle underbodies. The tape's cold resistance prevents cracking during winter conditions.

4. Interior Wiring Systems

For passenger compartment applications, the colored Automotive Wire Harness PVC Tape variants (XF-11 through XF-15) enable efficient cable identification while providing essential abrasion resistance and noise reduction.

Product Gallery

Technical FAQ

-

Q: What plasticizer is used in your PVC tape formulation?

A: Our Automotive Wire Harness PVC Tape utilizes Dioctyl Phthalate (DOP) as the primary plasticizer, which provides superior flexibility and low-temperature performance. This formulation meets automotive OEM specifications for cold resistance down to -40°C.

-

Q: How does the adhesive perform in high-temperature environments?

A: The pressure-sensitive adhesive in our XF-110 tape maintains bonding strength at continuous temperatures up to 130°C without degradation. This exceeds industry standards for engine compartment applications.

-

Q: What voltage rating do your tapes provide?

A: Our premium Automotive Wire Harness PVC Tape achieves dielectric strength ratings between 8-10kV/mm depending on the specific model. The XF-110 variant offers maximum electrical insulation for high-voltage EV applications.

-

Q: Are these tapes compliant with environmental regulations?

A: All our Automotive Wire Harness PVC Tapes strictly comply with ROHS directives (2011/65/EU) and contain no restricted substances. Our manufacturing processes emphasize sustainability.

-

Q: What installation techniques do you recommend?

A: For optimal performance with our Automotive Wire Harness PVC Tape, we recommend:

- Surface cleaning with appropriate automotive-grade cleaners

- Application at temperatures above 10°C

- 50% overlap wrapping technique for full coverage

- Moderate tension during application to prevent wrinkling

-

Q: How do color options impact performance?

A: While all colors provide identical electrical properties, black Automotive Wire Harness PVC Tape offers slightly superior UV resistance for exterior applications. Our color-coding system assists technicians in identifying circuit types during installation.

-

Q: Do you provide custom formulations?

A: JULU COUNTRY XIANGFAN SEALS FACTORY offers engineering support for custom tape formulations addressing specific OEM requirements including unique dimensions, adhesive properties, and specialized materials.

Industry References & Research

Future Development Outlook

The next generation of Automotive Wire Harness PVC Tape will focus on:

- Extended temperature performance for 800V EV architectures

- Self-healing formulations for micro-damage resistance

- Smart tape integration with embedded diagnostic capabilities

- Improved sustainability through bio-based PVC alternatives

- Nano-enhanced adhesives for superior bonding strength

JULU COUNTRY XIANGFAN SEALS FACTORY remains committed to advancing Automotive Wire Harness PVC Tape technology, focusing on the evolving needs of the global automotive industry through continuous R&D investment.

Visit Product Page for Detailed Specifications-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025