Official Website: https://www.qiangdatape.com

Phone: +86-15902204128

Mobile: +86-13932918280

Email: tony_qin@qjcxfmfj.com

Address: OFFICE BUILDING OF MANAGEMENT COMMITTEE OF SHIZISHAN HIGH-TECH ZONE, TONGLING, ANHUI, CHINA

Introduction: The Evolving Landscape of Fire Retardant Electrical Tape

In the modern industrial and construction environment, the need for reliable, safe, and high-performance fire retardant electrical tape is more prominent than ever before. Recent fires caused by electrical faults have underscored the importance of high-quality tape electrical insulation in both new constructions and maintenance scenarios. As regulations tighten and technology accelerates, the materials and features of products like fire retardant electrical tape have evolved remarkably.

This article, centered around the core keywords “fire retardant electrical tape,” “tape electrical insulation,” “electrical insulation tape,” “tape for construction,” and “pvc tape insulation,” explores the current industry trends, underpinning technologies, and application scenarios. Special focus will be given to the flagship product of JULU COUNTRY XIANGFAN SEALS FACTORY—the Flame Retardant Automotive Wire Harness PVC Tape.

The need for advanced insulation and fire protection has never been higher, and the advent of flame-retardant solutions marks a new standard in electrical and construction safety.

Industry Trends and Market Insights

- Growth in Demand: With increased urbanization and industrialization, the market for fire retardant electrical tape is projected to grow at a CAGR of 4.5% from 2024 to 2030 (MarketsandMarkets, 2023).

- Stringent Safety Regulations: Regulatory standards such as ROHS, UL510, BS EN 60454 and ASTM D-1000 are now minimum requirements for electrical insulation tapes in professional environments (IEC 60454).

- Material Advancements: Use of improved plasticizers (like DOP), flame-retardants, and eco-friendly PVC is now standard in products for pvc tape insulation.

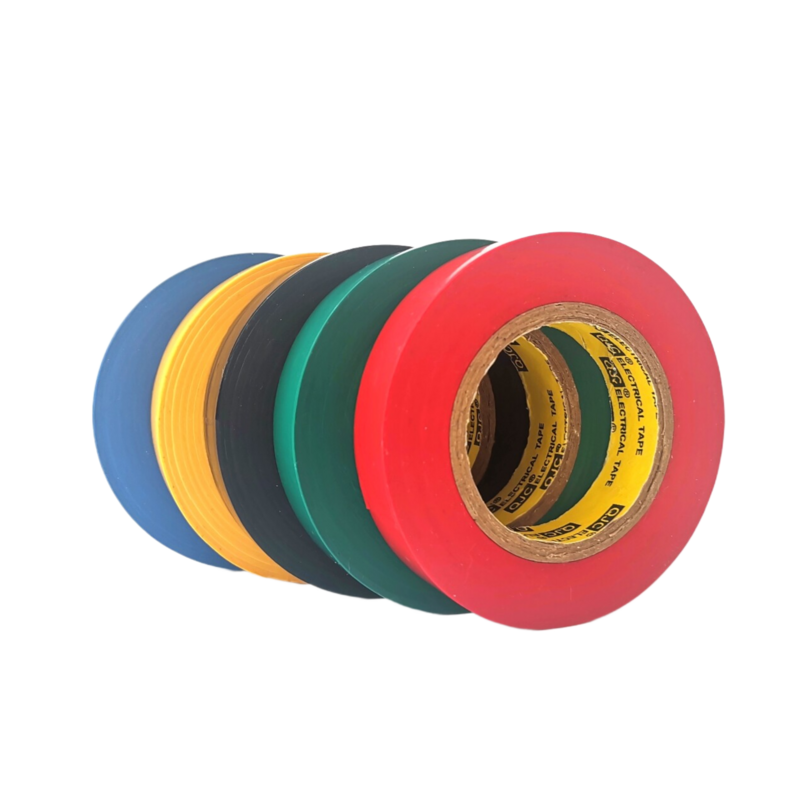

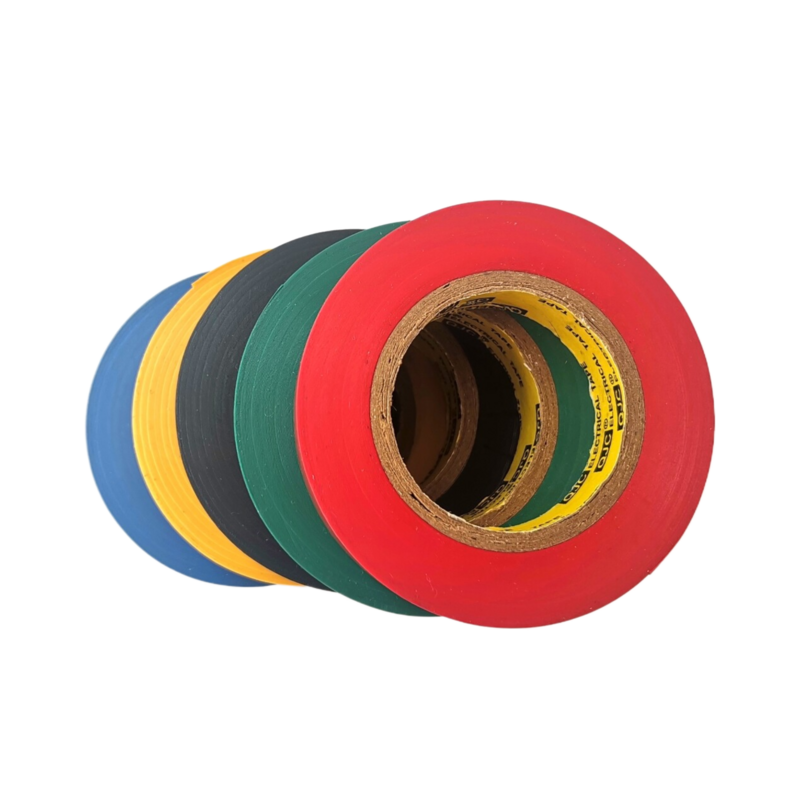

- Customization and Application-Specific Solutions: The rise of automotive, data center, and energy construction sectors has led to demand for custom color-coding, thickness, widths, and temperature ratings of insulation tapes.

Highlight Product: Flame Retardant Automotive Wire Harness PVC Tape

Codes: XF-FR085 XF-FR100 XF-FR110 XF-FR120 XF-FR130

Available Colors: Black, Red, White, Green, Blue, Yellow, Grey

Key Features:

- Manufactured using high-quality PVC film and DOP plasticizer

- High performance pressure-sensitive adhesive

- Excellent electrical insulation and voltage resistance

- Flame retardant, cold resistant, and compliant with ROHS

- Multiple width and thickness options available

- Ideal for automotive, construction, and professional installations

Technical Parameter Table: Comparison of Fire Retardant Electrical Tape

| Parameter | Industry Standard Value | XF-FR110 (JULU COUNTRY XIANGFAN SEALS FACTORY) | Other Competitor Tape |

|---|---|---|---|

| Material | PVC + Flame Retardant | PVC (DOP, flame retardant additive) | PVC (chloride-based flame retardant) |

| Standard Thickness (mm) | 0.11 - 0.20 | 0.11 | 0.13 |

| Width (mm) | 10 - 25 | 17 / 19 / 22 | 18 |

| Dielectric Strength (kV/mm) | > 40 | 50 | 38 |

| Adhesion to Steel (N/10mm) | > 1.8 | 2.1 | 1.7 |

| Fire Retardancy | Self-extinguishing | Self-extinguishing (Tested) | Self-extinguishing |

| Temperature Range (℃) | -20 ~ 80 | -30 – 80 | -10 – 60 |

| ROHS Compliant | Required | Yes | Varies |

Data Visualization: Performance & Industry Trends

Applications of Fire Retardant Electrical Tape

- Automotive Industry: Wire harness bundling, loom protection, and color-coded circuit identification.

- Construction Sites: Junction box insulation, cable management, and phase marking for high-rise or industrial sites using tape for construction.

- Home Electrical Repairs: General-purpose electrical insulation tape for household wiring improvements.

- Industrial Equipment Protection: Wrapping and insulating high voltage connectors and transformer terminals for enhanced safety.

- Data Center Infrastructure: Color-coded pvc tape insulation to meet complex identification needs in large networks.

- Public Infrastructure: Metro, tunnel, or power station construction complying with advanced fire-safety codes.

Expert Q&A: Fire Retardant Electrical Tape

Why Choose JULU COUNTRY XIANGFAN SEALS FACTORY?

- Authority: Over 20 years of expertise in electrical insulation research and PVC tape manufacturing.

- Professional Standards: ISO-certified processes, advanced lab facilities, and a reputation for strict quality control.

- Trustworthy Partner: Consistent export performance to demanding international markets, including Europe and North America; proven by repeat buyers and positive technical audits.

- Comprehensive Solutions: Covers all client requirements—from product customization to full technical documentation and logistics.

- Direct Factory Service: Efficient communication and full support, direct from the manufacturer's engineering team.

Future Outlook & Industry Development

The next decade will see increasing application requirements for fire retardant electrical tape, especially as electrification, e-mobility, IoT, and clean energy megatrends accelerate. Research into advanced flame-retardant chemistries (halogen-free, eco-safe) and smart tapes embedding sensors (temperature, current leakage) are emerging on the horizon (IEEE Xplore, 2019).

Conclusion

Selecting the right fire retardant electrical tape is no longer just about meeting basic insulation needs; it is integral to modern system safety, regulatory compliance, and operational reliability. Whether for automotive harnessing, home renovation, or large-scale construction, products like the Flame Retardant Automotive Wire Harness PVC Tape manufactured by JULU COUNTRY XIANGFAN SEALS FACTORY are setting the standard for what high-performance, reliable, and safe electrical insulation tape should be.

For further technical reading and standards, explore authoritative sources:

- IEC 60454-3-1: https://www.nti-audio.com/Portals/0/data/en/standards/IEC60454-3-1.pdf

- IEEE Journal: https://ieeexplore.ieee.org/document/8422935

- Industry Insights: MarketsandMarkets Report

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025