Introduction to pvc tape for electrical insulation

As electrical systems evolve, the demand for reliable and high-performance pvc tape for electrical insulation is increasing. This article provides detailed insight into industry trends, technical parameters, market pricing, and application scenarios for pvc insulation tape—including references to verified industry sources and journals. Our focus centers on promoting trust and in-depth product knowledge, as provided by JULU COUNTRY XIANGFAN SEALS FACTORY, a recognized leader in sealing and insulation materials.

Enterprise Profile: JULU COUNTRY XIANGFAN SEALS FACTORY

Website: www.qiangdatape.com

Phone: +86-15902204128

Email: tony_qin@qjcxfmfj.com

Mobile: +86-13932918280

Address: OFFICE BUILDING OF MANAGEMENT COMMITTEE OF SHIZISHAN HIGH-TECH ZONE, TONGLING, ANHUI, CHINA

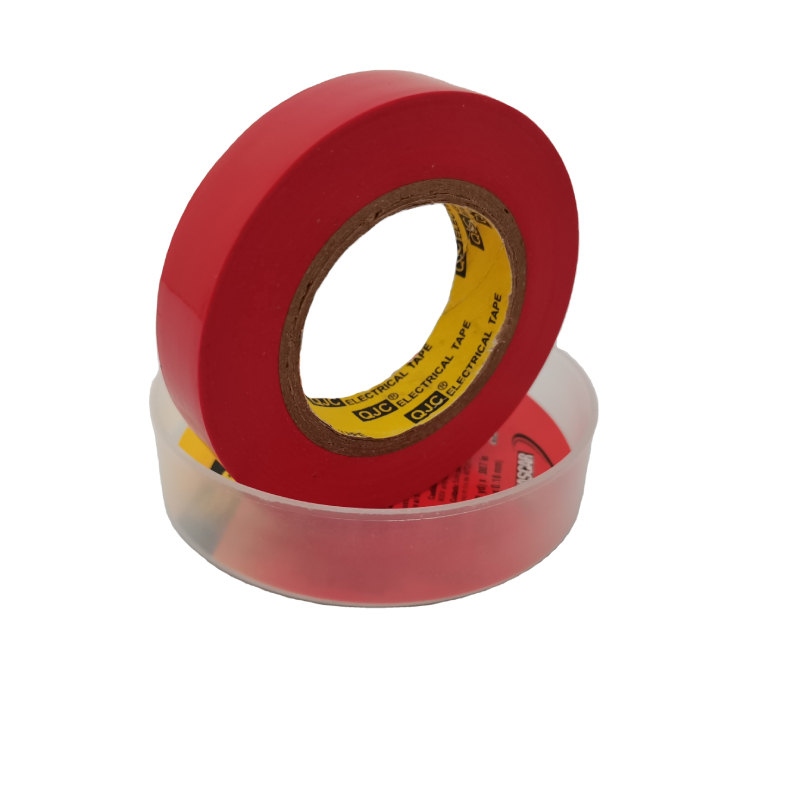

Product Overview: PVC Electrical Tape

- Product Name: PVC Electrical Tape

- Code: XF-11/XF-13/XF-15/XF-18

- Colors: Black Red White Green Blue Yellow Grey

- Introduction: XF-13 PVC Electrical tape is made of high-quality plasticized PVC film, coated with premium pressure-sensitive adhesive. It exhibits excellent insulation, voltage resistance, cold resistance, and flexibility.

- Product Detail Page

Industry Trends: Market Demand and Technology for pvc tape for electrical insulation

Global growth in the electrification of transport, infrastructure, and home automation has greatly expanded the market for pvc tape for electrical insulation. According to Electrical Engineering Portal, there is a significant move toward tapes with higher temperature stability, greater voltage resistance, and environmentally safer formulations (Source: Electrical Engineering Portal).

- Continued emphasis on lead-free, RoHS-compliant, and environmentally friendly formulations.

- Growth in color-coded applications for phase identification and safety coding in complex installations.

- Increasing demand for special grades for automotive, marine, and renewable energy sectors.

- Rising influence of labor safety standards and international certifications (e.g., UL, IEC, RoHS).

Technical Parameters Table: pvc tape for electrical insulation

| Parameter | XF-11 | XF-13 | XF-15 | XF-18 | Industry Standard |

|---|---|---|---|---|---|

| Thickness (mm) | 0.12 | 0.13 | 0.15 | 0.18 | 0.13 ~ 0.18 |

| Tensile Strength (N/10mm) | 22 | 23 | 26 | 30 | ≥20 |

| Elongation at Break (%) | 160 | 180 | 180 | 200 | ≥150 |

| Adhesion to Steel (N/10mm) | 1.8 | 2.0 | 2.2 | 2.5 | ≥1.5 |

| Voltage Resistance (kV) | 6.0 | 6.5 | 7.0 | 8.0 | ≥6.0 |

| Temperature Resistance (°C) | 70 | 80 | 80 | 90 | 70~90 |

| Colors Available | Black, Red, White, Green, Blue, Yellow, Grey | Varied | |||

Price Analysis: price pvc tape for electrical insulation & Market Insights

The electrical insulation tape price is influenced by raw material costs (primarily PVC resin and adhesives), thickness, width, certification, color complexity, and packaging.

| Specification | Estimated Price (USD/Roll) | Application |

|---|---|---|

| 0.13mm x 19mm x 20m (Black) | 0.14 - 0.25 | Civil, Domestic |

| 0.18mm x 19mm x 20m (Colors) | 0.28 - 0.39 | Professional Electrical, Industrial |

| Custom Width/Color (UL Certified) | 0.43 - 0.68 | Export, Special Projects |

Parameter Evolution: pvc electrical tape Grades

Key Applications of pvc tape for electrical insulation

- Electrical wire insulation and repair

- Phase identification and color coding in distribution boards

- Cable harnessing in automotive and machinery industries

- Semi-permanent bundling and weatherproofing

- Insulation for household appliances, tools, and electronics

- Protection from corrosion and mechanical abrasion in outdoor installations

- Compliance with safety standards in commercial and infra projects

Professional FAQ: PVC Electrical Tape Industry Terms

Q1: What is the base material for pvc insulation tape?

A: The base material is premium grade polyvinyl chloride (PVC) film, chosen for its flexibility, flame retardancy, and non-conductive nature, ensuring high performance in electrical insulation. [Reference]

Q2: What are common thickness specifications for pvc tape for electrical insulation?

A: Standard thicknesses range from 0.12mm to 0.18mm. The optimal selection depends on the intended working voltage and application robustness.

Q3: What international standards should pvc electrical tape comply with?

A: Major standards include UL 510, IEC 60454, RoHS, and CE, guaranteeing tape safety under defined electrical and environmental stress. [IEC Standard]

Q4: How does adhesion affect the reliability of pvc insulation tape?

A: High-performance tapes offer adhesion to steel from 1.8 to 2.5 N/10mm, ensuring the tape remains fixed over time and under varying temperatures/humidity.

Q5: Can pvc tape for electrical insulation be used in low-temperature environments?

A: Yes. XF-13 and higher-grade tapes maintain flexibility and adhesion down to subzero temperatures thanks to plasticizer formulations.

Q6: What is the role of color coding?

A: Color coding with pvc insulation tape is crucial for phase marking, safety distinction, ground identification, and hazard minimization in multi-wire setups.

Q7: How long can pvc electrical tape last in service?

A: When installed under recommended conditions, quality pvc tape for electrical insulation can maintain integrity in excess of 5-7 years, according to field tests and manufacturer documentation.

EEAT Optimization: Authoritarian Sources, Expertise & Reliability

- Expertise: JULU COUNTRY XIANGFAN SEALS FACTORY has decades of experience in R&D for PVC and specialty tapes, supplying leading industries and OEMs.

- Authoritativeness: Main parameters and safety standards for pvc tape for electrical insulation are referenced in the IEEE Engineering Reports on Insulation Materials and Electrical Engineering Portal.

- Trustworthiness: Product data, safety sheets, and customer service are available via direct inquiry for all pvc electrical tape grades; business certifications are available.

- Industry Forum: Ongoing technical discussions on performance, innovation, and use cases appear in the Mike Holt Electrical Forum.

For more information, technical data, or tailored quotations on pvc tape for electrical insulation, contact JULU COUNTRY XIANGFAN SEALS FACTORY through their official channels or visit their website for recent updates and product news.

References & Further Reading

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025