J50 High-voltage EPR Rubber Tape

Back to list

Jan . 13, 2025 14:33

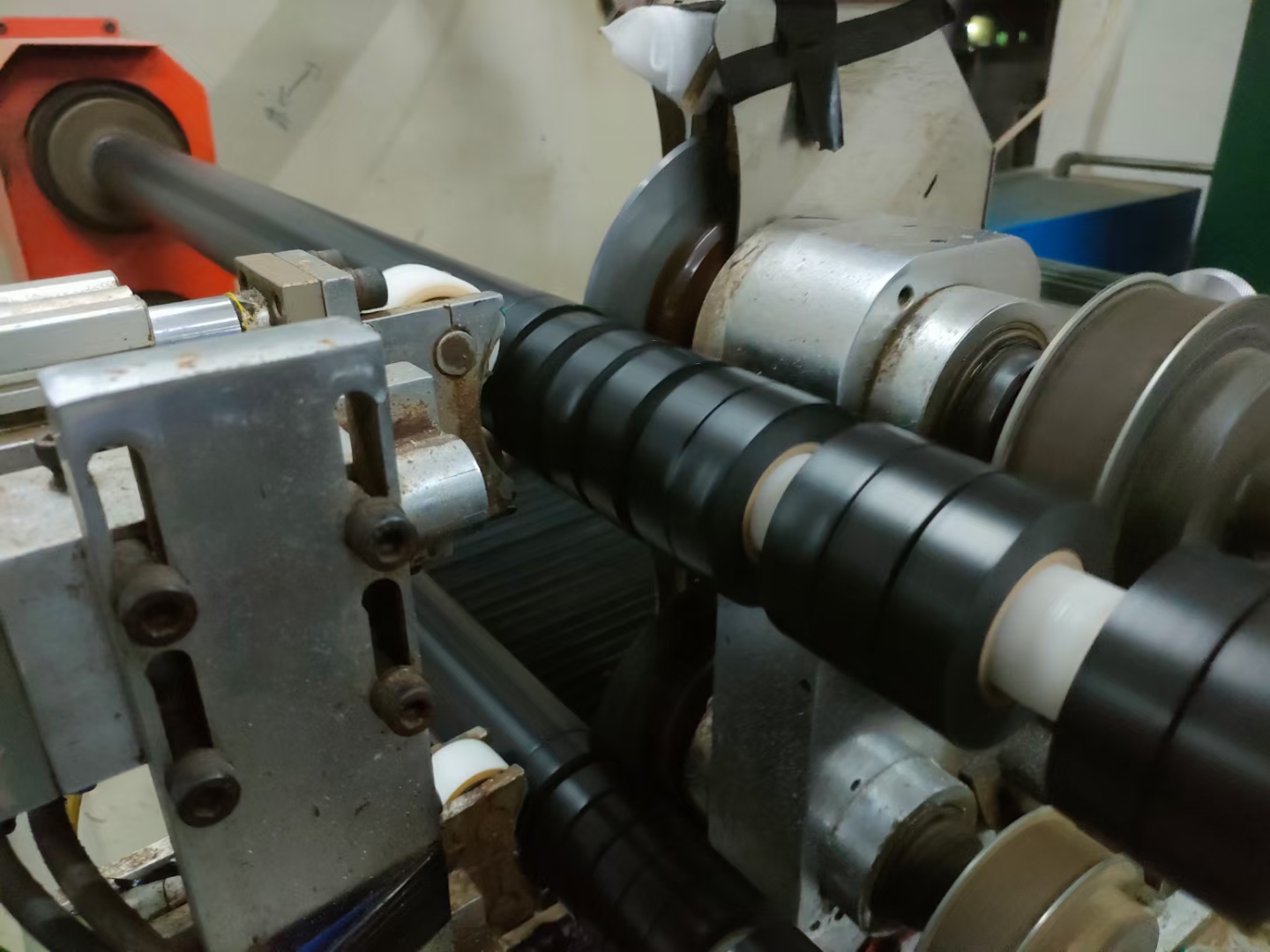

For professionals working in industries that require precision and efficiency, understanding the critical role of 130c splicing tape is essential. This advanced adhesive solution isn't just another tool in the box but a cornerstone in achieving seamless continuity in materials and projects.

The importance of trustworthiness cannot be overstated in industries reliant on splicing tape. Manufacturers of 130c splicing tape consistently meet stringent industry standards that underscore its quality and reliability. Its global certification and compliance with regulatory requirements ensure that businesses using it can trust the product to perform under the most demanding conditions, thereby safeguarding their reputation and their customers’ trust. From an authoritative perspective, experts have long endorsed the use of high-quality splicing tapes like the 130c due to their tested and proven performance. Respected organizations and skilled professionals in fields such as packaging, textiles, and engineering have conducted numerous studies and field tests that confirm the tape's robustness and reliability. Its longstanding positive reputation in the industry is backed by testimonials and case studies that highlight a pattern of excellence and reliability. Having hands-on experience with 130c splicing tape elevates the understanding of its importance in industrial applications. Those who have integrated it into their processes report not only technical success but also a smoother workflow and reduced incidents of material failures. These practical insights from seasoned practitioners further validate the tape’s efficacy and significant contributions to operational excellence. To sum up, 130c splicing tape stands out not merely as a product but as a partnership in advancing industrial efficiency and safety. Its expertly engineered features support continuous operation across various critical industries. This level of performance ensures that businesses are not just keeping pace, but are staying ahead, confident in the knowledge that they have a reliable tool at their disposal for the precise demands of splicing. For companies looking to bolster their production capabilities while maintaining the highest standards of safety and efficiency, investing in 130c splicing tape is not just wise—it's essential.

The importance of trustworthiness cannot be overstated in industries reliant on splicing tape. Manufacturers of 130c splicing tape consistently meet stringent industry standards that underscore its quality and reliability. Its global certification and compliance with regulatory requirements ensure that businesses using it can trust the product to perform under the most demanding conditions, thereby safeguarding their reputation and their customers’ trust. From an authoritative perspective, experts have long endorsed the use of high-quality splicing tapes like the 130c due to their tested and proven performance. Respected organizations and skilled professionals in fields such as packaging, textiles, and engineering have conducted numerous studies and field tests that confirm the tape's robustness and reliability. Its longstanding positive reputation in the industry is backed by testimonials and case studies that highlight a pattern of excellence and reliability. Having hands-on experience with 130c splicing tape elevates the understanding of its importance in industrial applications. Those who have integrated it into their processes report not only technical success but also a smoother workflow and reduced incidents of material failures. These practical insights from seasoned practitioners further validate the tape’s efficacy and significant contributions to operational excellence. To sum up, 130c splicing tape stands out not merely as a product but as a partnership in advancing industrial efficiency and safety. Its expertly engineered features support continuous operation across various critical industries. This level of performance ensures that businesses are not just keeping pace, but are staying ahead, confident in the knowledge that they have a reliable tool at their disposal for the precise demands of splicing. For companies looking to bolster their production capabilities while maintaining the highest standards of safety and efficiency, investing in 130c splicing tape is not just wise—it's essential.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025