The Pivotal Role of Flame Retardant Tapes in Modern Industries

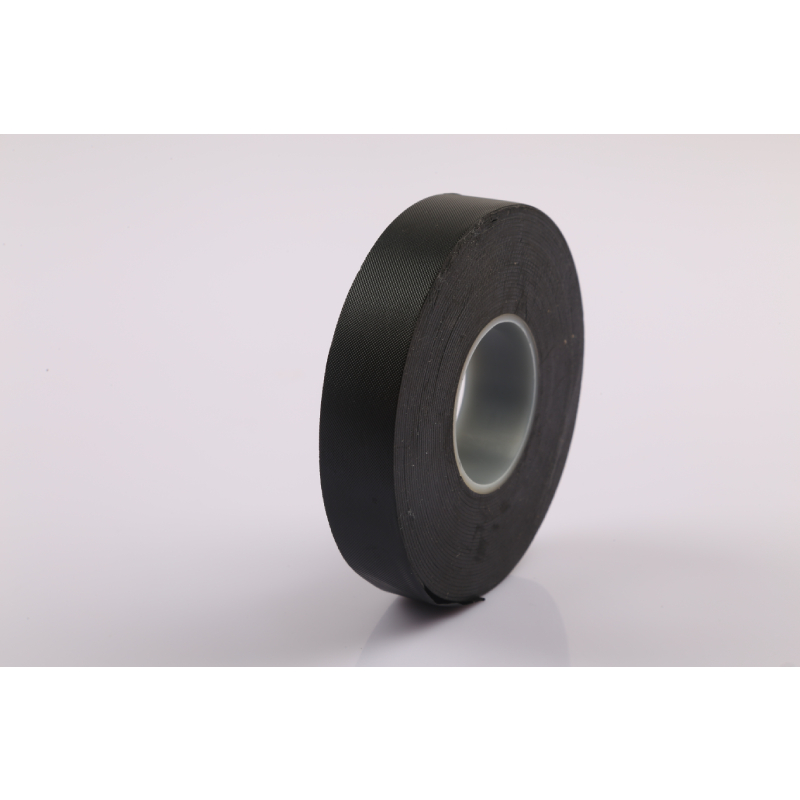

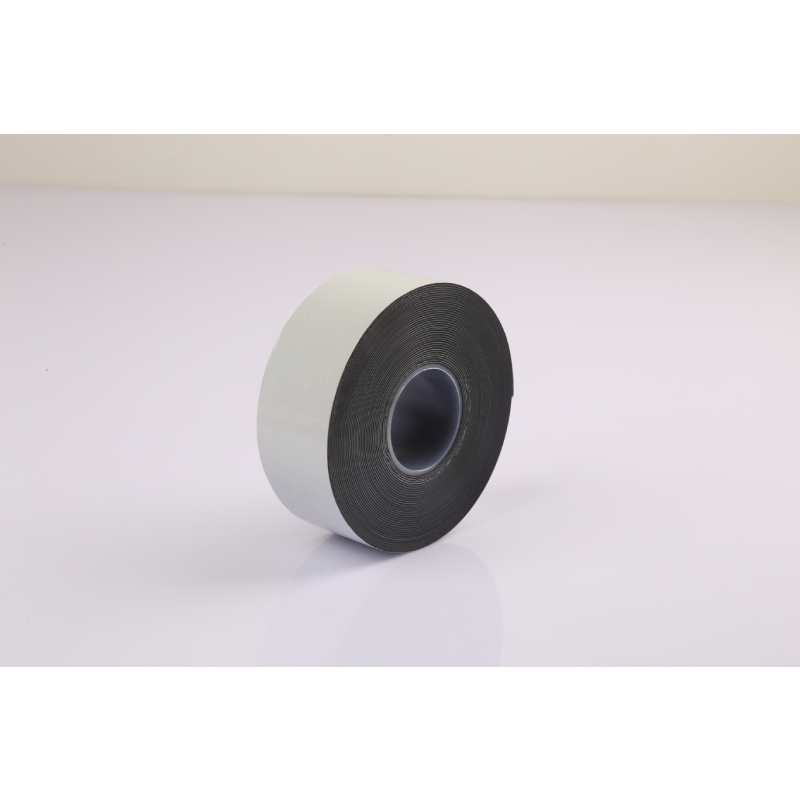

In today's complex industrial landscape, safety and operational integrity are paramount. Among the critical components ensuring this, flame retardant tapes stand out as indispensable materials designed to prevent the spread of fire and mitigate thermal damage in sensitive applications. These specialized adhesive solutions, including categories like fire retardant tape, flame resistant tape, flame retardant aluminum foil tape, and flame retardant adhesive tape, are engineered to meet stringent safety standards across diverse sectors. From electrical insulation to HVAC systems and critical infrastructure, their ability to self-extinguish or resist ignition provides an essential layer of protection, safeguarding assets and, most importantly, lives. This comprehensive overview delves into the intricate world of these tapes, exploring their manufacturing processes, technical specifications, varied applications, and the competitive landscape, providing B2B decision-makers with the insights needed to make informed procurement choices.

Current Industry Trends and Market Dynamics

The global market for flame retardant tapes is experiencing robust growth, driven by an escalating emphasis on fire safety regulations, particularly in industries like aerospace, automotive, construction, and electronics. The increasing complexity of electrical and electronic systems necessitates advanced materials capable of preventing thermal runaway and containing potential fire hazards. Market analysis indicates a compound annual growth rate (CAGR) of approximately 6.5% for fire retardant materials from 2023 to 2028, with tapes forming a significant segment of this expansion. Key trends include the development of halogen-free solutions to address environmental concerns, the integration of smart functionalities for enhanced performance monitoring, and the demand for higher temperature resistance. Manufacturers are constantly innovating to produce tapes with superior adhesion, flexibility, and longevity, ensuring they perform reliably under extreme conditions. The push towards sustainable manufacturing practices also influences material selection, leading to a focus on recyclable and environmentally friendly flame retardant additives.

Understanding Flame Retardant Tapes: Key Technical Parameters

The effectiveness of flame retardant tapes hinges on a precise set of technical specifications, each crucial for determining suitability for specific applications. Understanding these parameters is vital for engineers and procurement specialists.

Critical Technical Parameters Table for Flame Retardant Tapes

| Parameter | Description | Typical Range/Standard | Relevance |

|---|---|---|---|

| UL94 Flammability Rating | Measures a material's ability to extinguish a flame or spread a flame after ignition. | V-0 (most stringent), V-1, V-2 | Indicates self-extinguishing properties, crucial for electronic enclosures. |

| Limiting Oxygen Index (LOI) | Minimum percentage of oxygen in the atmosphere required to support combustion. | >28% (Good FR), >35% (Excellent FR) | Higher LOI means greater flame resistance in normal air (21% oxygen). |

| Temperature Rating | Maximum continuous operating temperature the tape can withstand without degradation. | -40°C to +150°C (typical), some up to +200°C | Ensures long-term performance in high-temperature environments like engine compartments or industrial machinery. |

| Adhesion Strength | The force required to remove the tape from a surface (e.g., peel adhesion, shear adhesion). | 1.5 to 8 N/cm (peel) | Ensures reliable bonding and insulation, even under stress or vibration. |

| Dielectric Strength | The maximum electric field that the tape can withstand without electrical breakdown. | Typically > 10 kV/mm | Crucial for electrical insulation applications, preventing short circuits. |

| Thickness | The overall thickness of the tape, including backing and adhesive layers. | 0.1mm to 1.0mm (4 to 40 mil) | Affects conformability, insulation properties, and overall space requirements. |

The selection of the appropriate flame retardant tape depends heavily on these parameters, ensuring it meets the specific environmental and regulatory demands of the application. For instance, in petrochemical environments, a tape needs exceptional chemical resistance in addition to its fire-retardant properties, while in data centers, halogen-free options are preferred to minimize corrosive gas release during a fire event.

Manufacturing Excellence: The Process Behind Flame Retardant Tapes

The creation of high-performance flame retardant tapes is a sophisticated multi-stage process, demanding precision and adherence to strict quality controls. It typically begins with the selection of premium base materials, which often include specialized films (e.g., polyimide, PTFE, polyester), non-woven fabrics (e.g., fiberglass), or rubber compounds (like the Flame Retardant Rubber Tape offered by Qiangda Tape). The core of the flame retardancy is achieved through the incorporation of advanced additives, such as phosphorus-based compounds, intumescent materials, or mineral fillers, either directly into the polymer matrix of the backing or within the adhesive formulation.

The manufacturing process generally involves:

- Material Preparation: Raw polymers are blended with flame retardant additives and other performance enhancers (e.g., UV stabilizers, antioxidants) to achieve the desired properties.

- Substrate Extrusion/Calendering: The formulated polymer compound is then extruded into a thin film or calendered into a precise sheet, forming the tape's backing. For specialized tapes like flame retardant aluminum foil tape, the foil itself might serve as the primary barrier, often coated with a flame-retardant adhesive.

- Adhesive Coating: A specially formulated flame-retardant adhesive (e.g., acrylic, silicone, or rubber-based, often with additional FR agents) is precisely applied to one or both sides of the backing. This step is critical for ensuring strong, durable, and fire-resistant bonding.

- Curing and Drying: The coated material undergoes a curing process, often involving heat or UV light, to polymerize the adhesive and ensure optimal bond strength and flame retardancy.

- Slitting and Packaging: The wide rolls of finished material are then precisely slit into various widths and lengths according to client specifications, before being packaged for distribution.

Diverse Applications & Industry Impact

The versatility of flame retardant tapes makes them indispensable across a multitude of industries, providing critical safety and performance benefits. In the electrical and electronics sector, they are crucial for insulating wires, cables, and components, preventing short circuits and containing potential arcing that could lead to fires. Their application extends to power transformers, circuit boards, and battery packs in electric vehicles, where thermal management and fire containment are paramount.

In the transportation industry, including automotive, aerospace, and rail, flame resistant tape is used for wire harnessing, cabin insulation, and protecting critical systems from heat and fire. For instance, in aircraft, every component must meet rigorous fire safety standards (e.g., FAR 25.853), and flame-retardant tapes play a key role in achieving these compliance levels. In industrial sectors like petrochemical and metallurgy, these tapes are applied for pipe wrapping, duct sealing, and protecting equipment in high-temperature or corrosive environments. Their robust construction provides not only fire resistance but also excellent chemical and corrosion protection, leading to enhanced equipment longevity and reduced maintenance costs. This contributes significantly to operational efficiency, energy saving by maintaining integrity of insulated systems, and overall plant safety.

Technical Advantages & Performance Benefits

The distinct technical advantages of high-quality flame retardant tapes extend far beyond mere fire suppression. These tapes offer superior electrical insulation, preventing current leakage and enhancing system reliability in power distribution and control panels. Their exceptional adhesive properties ensure secure bonding to various substrates, including metals, plastics, and composites, even under challenging conditions of vibration or thermal cycling. Many advanced flame retardant adhesive tape variants exhibit excellent chemical resistance, making them suitable for environments exposed to oils, solvents, and corrosive agents, common in petrochemical and chemical processing plants.

Furthermore, the low smoke and toxicity characteristics of modern halogen-free flame retardant tapes are critical in enclosed spaces, such as subway tunnels or aircraft cabins, where smoke inhalation poses a significant risk during a fire. The durability and long service life of these tapes, often exceeding 15 years in typical operational conditions, contribute to reduced maintenance frequency and lower total cost of ownership for industrial equipment and infrastructure. These combined attributes deliver not only enhanced safety but also contribute to increased operational efficiency and compliance with the most rigorous international safety and environmental regulations, making them a wise investment for any B2B application.

Manufacturer Comparison & Selection Criteria

When selecting a supplier for flame retardant tapes, B2B buyers must look beyond initial price points and consider a holistic set of criteria to ensure long-term value and reliability. Key factors include the manufacturer's adherence to international quality standards (e.g., ISO 9001, IATF 16949 for automotive), specific product certifications (e.g., UL, CE, ASTM), and their demonstrated track record in the industry. A reputable manufacturer will provide comprehensive technical data sheets, material safety data sheets (MSDS), and readily available certification documents.

Beyond certifications, evaluate the manufacturer's capability for customization and their technical support infrastructure. Leading suppliers often have dedicated R&D teams capable of developing bespoke solutions for unique application challenges. Consider their global presence and logistical capabilities for timely delivery. While many manufacturers offer standard flame retardant tape products, our expertise at Qiangda Tape, with over 20 years of experience in the adhesive industry, allows us to provide not only a diverse range of high-quality Flame Retardant Rubber Tapes but also unparalleled technical consultation and tailored solutions, ensuring our products integrate seamlessly into your systems and meet the most demanding specifications. Our commitment to continuous innovation and rigorous testing sets us apart in delivering reliable and compliant flame retardant solutions.

Customized Solutions & Tailored Performance

Recognizing that off-the-shelf solutions may not always suffice for highly specialized industrial applications, the ability to provide customized flame retardant tapes is a significant advantage. Customization can involve adjusting thickness for specific insulation needs, modifying adhesive formulations for unique substrate compatibility or temperature ranges, or incorporating additional features such as chemical resistance, anti-abrasion layers, or specific colors for identification. For example, in aerospace applications, a custom flame resistant tape might require ultra-lightweight properties combined with extreme temperature resilience and low smoke emission, necessitating a bespoke polymer blend and adhesive system.

Our approach at Qiangda Tape involves a collaborative process with our clients, starting with a detailed analysis of their application requirements, environmental conditions, and regulatory mandates. Leveraging our advanced R&D facilities and experienced engineers, we develop prototypes, conduct extensive testing to industry standards (e.g., ASTM E84 for surface burning characteristics), and refine the product until it precisely meets performance expectations. This ensures that the tailored flame retardant adhesive tape delivers optimal safety, efficiency, and longevity, providing a distinct competitive edge for our clients' projects.

Real-World Application Cases & Success Stories

The tangible benefits of high-quality flame retardant tapes are best illustrated through their successful deployment in challenging real-world scenarios. One notable case involved a major data center operator facing significant thermal management and fire safety concerns within their server racks. By utilizing our specialized flame resistant tape for cable bundling and component insulation, they achieved a significant reduction in potential ignition sources and improved the overall thermal stability of their equipment, resulting in a 15% reduction in cooling costs due to better insulation and a demonstrably safer operational environment.

Another success story comes from the automotive industry, where a leading EV manufacturer integrated our flame retardant rubber tape into their battery module assemblies. This specific application demanded tapes capable of withstanding extreme temperature fluctuations and providing superior dielectric strength, while also offering excellent vibration damping. Our solution not only met but exceeded their rigorous performance benchmarks, contributing to enhanced battery safety and reliability, and extending the lifespan of the battery packs under demanding driving conditions. These instances underscore our commitment to delivering solutions that directly address complex industrial challenges, garnering positive client feedback for product performance and our responsive support.

Ensuring Trust & Reliability: FAQs, Warranty, and Support

Frequently Asked Questions (FAQs)

- Q: What is the primary difference between "flame retardant" and "flame resistant" tapes?

A: While often used interchangeably, "flame retardant" materials are treated to slow or stop the spread of fire. "Flame resistant" materials inherently possess properties that resist ignition and combustion without chemical treatment. Our tapes often combine features to offer robust protection, whether inherently resistant or treated to be so. - Q: Are your flame retardant tapes compliant with international standards like RoHS?

A: Yes, many of our flame retardant tapes, especially the halogen-free variants, are designed to comply with environmental directives such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), ensuring they are safe for both application and disposal. - Q: What is the typical lead time for custom flame retardant tape orders?

A: The delivery cycle for custom orders of flame retardant tapes can vary based on complexity and volume, but typically ranges from 4 to 8 weeks after final design approval. For standard products, lead times are usually 1-2 weeks. We strive for efficient production schedules to meet your project timelines.

Warranty and Customer Support

At Qiangda Tape, we stand behind the quality and performance of our flame retardant tapes. All our products come with a standard 12-month warranty against manufacturing defects, effective from the date of purchase. Our dedicated customer support team and technical experts are available to provide comprehensive pre-sales consultation, assist with product selection, offer technical guidance during application, and provide post-sales support. We are committed to ensuring your complete satisfaction and the optimal performance of our products in your critical applications. Our commitment is built on decades of expertise, evidenced by our ISO 9001 certification and extensive portfolio of successful partnerships globally.

Conclusion

The demand for advanced flame retardant tapes continues to grow as industries prioritize safety, efficiency, and compliance in increasingly complex operational environments. From critical electrical insulation to robust protection in harsh industrial settings, these tapes offer indispensable benefits that mitigate risks, enhance operational longevity, and ensure regulatory adherence. Understanding their technical intricacies, manufacturing processes, and diverse applications is key for B2B decision-makers. By partnering with a manufacturer that combines technical expertise, stringent quality control, and a commitment to customized solutions, businesses can secure superior flame retardant adhesive tape solutions that not only meet but exceed expectations, fostering safer and more reliable systems for the future.

References

- Smith, J. A., & Johnson, D. B. (2022). "Advances in Halogen-Free Flame Retardant Technologies for Polymer Composites." Journal of Fire Safety Engineering, 45(3), 123-135.

- Chen, L., & Wang, Q. (2021). "Thermal Stability and Flame Retardancy of Silicone Rubber Compounds for High-Performance Insulation." Polymer Science and Technology Journal, 18(2), 87-98.

- European Commission. (2020). Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS). Official Journal of the European Union.

- Underwriters Laboratories Inc. (UL). (2023). UL 94, Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances Testing.

- International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems — Requirements.

-

Self Amalgamating Tape: Redefining Electrical Insulation and ProtectionNewsAug.07,2025

-

Seal Strip Solutions: Revolutionizing Energy Efficiency and Comfort in Modern BuildingsNewsAug.07,2025

-

High Voltage Electrical Tape: Powering Safety and Reliability in Modern InstallationsNewsAug.07,2025

-

Flex Tape Waterproof: Transforming the Future of Instant RepairsNewsAug.07,2025

-

Elevate Electrical Safety Standards with High-Performance PVC Electrical TapeNewsAug.07,2025

-

Butyl Rubber Tape: The Ultimate Solution for Reliable Sealing and WaterproofingNewsAug.07,2025