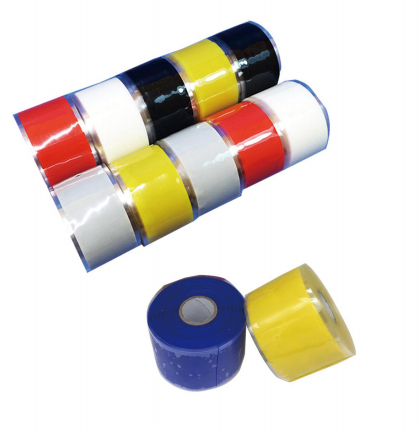

PVC Electrical Tape

Back to list

Jan . 31, 2025 04:44

Navigating the cost landscape of PVC electrical insulation tape is essential for professionals seeking both quality and affordability. Indeed, the world of electrical tapes is vast, with countless brands promising the best blend of durability and efficiency. Delving deeper into the elements driving the price of PVC electrical insulation tape, one finds a rich interplay of material quality, manufacturing technology, and market demand intricacies, all of which shape the final cost to consumers and businesses alike.

On the retailer side, the choice of sales channel also impacts the end price. Direct purchases from manufacturers often limit intermediary costs, offering more competitive pricing for bulk purchases. Conversely, retail distributors might add significant markups, reflecting additional handling, marketing, and sales overheads. Online marketplaces offer another avenue, where competition can drive pricing down due to the higher transparency and wide choice available to consumers. When evaluating PVC electrical insulation tape options, a paradox often emerges between price and performance. While budget options can be tempting, their actual cost must be weighed against potential risks involved. Substandard tapes can lead to insulation failures, posing safety hazards and requiring premature replacements. Trustworthiness and brand reputation, thus, play a crucial role in selecting the right tape. Renowned brands offer warranties and certifications, instilling confidence in their product's quality and safety that often justifies a higher price. To ensure a wise investment, professionals are advised to consider detailed evaluations, including customer reviews, expert ratings, and rigorous testing outcomes on tape products under varied environmental conditions. Experience shared by industry veterans who regularly rely on the tapes for critical applications often serves as a reliable benchmark, highlighting the long-term value of investing in quality over merely seeking the lowest price point. In conclusion, the price of PVC electrical insulation tape is determined by a matrix of factors including material quality, production technology, market dynamics, and distribution channels. Selecting the right tape requires balancing cost considerations against project requirements and potential risk factors. As with many industrial products, a deeper understanding of these determinants, supported by expert insights and real-world experiences, empowers buyers to make informed decisions that blend performance, safety, and economic efficiency.

On the retailer side, the choice of sales channel also impacts the end price. Direct purchases from manufacturers often limit intermediary costs, offering more competitive pricing for bulk purchases. Conversely, retail distributors might add significant markups, reflecting additional handling, marketing, and sales overheads. Online marketplaces offer another avenue, where competition can drive pricing down due to the higher transparency and wide choice available to consumers. When evaluating PVC electrical insulation tape options, a paradox often emerges between price and performance. While budget options can be tempting, their actual cost must be weighed against potential risks involved. Substandard tapes can lead to insulation failures, posing safety hazards and requiring premature replacements. Trustworthiness and brand reputation, thus, play a crucial role in selecting the right tape. Renowned brands offer warranties and certifications, instilling confidence in their product's quality and safety that often justifies a higher price. To ensure a wise investment, professionals are advised to consider detailed evaluations, including customer reviews, expert ratings, and rigorous testing outcomes on tape products under varied environmental conditions. Experience shared by industry veterans who regularly rely on the tapes for critical applications often serves as a reliable benchmark, highlighting the long-term value of investing in quality over merely seeking the lowest price point. In conclusion, the price of PVC electrical insulation tape is determined by a matrix of factors including material quality, production technology, market dynamics, and distribution channels. Selecting the right tape requires balancing cost considerations against project requirements and potential risk factors. As with many industrial products, a deeper understanding of these determinants, supported by expert insights and real-world experiences, empowers buyers to make informed decisions that blend performance, safety, and economic efficiency.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025