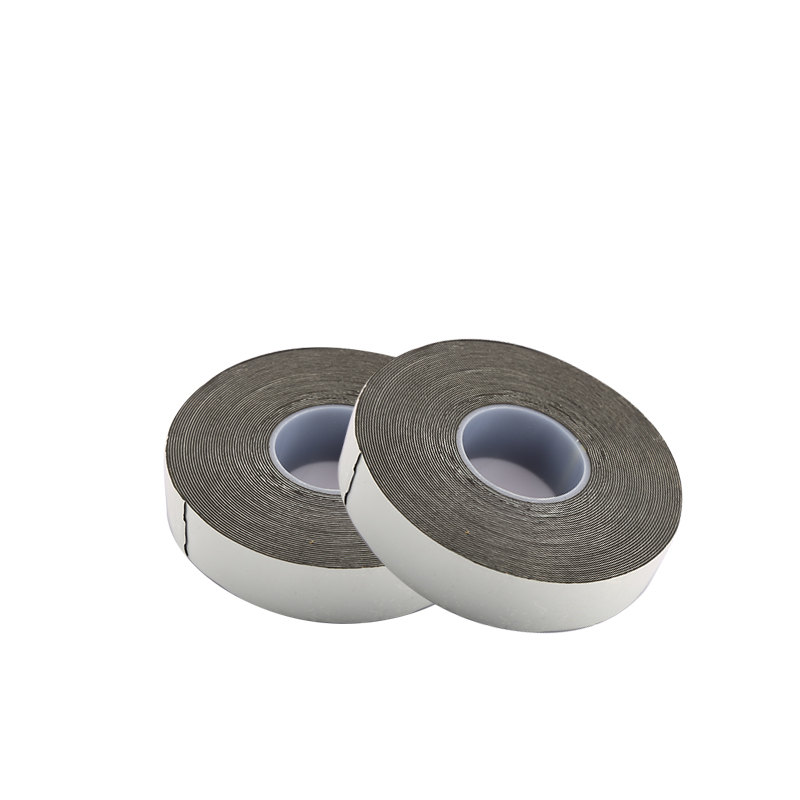

J50 High-voltage EPR Rubber Tape

Back to list

Feb . 12, 2025 13:49

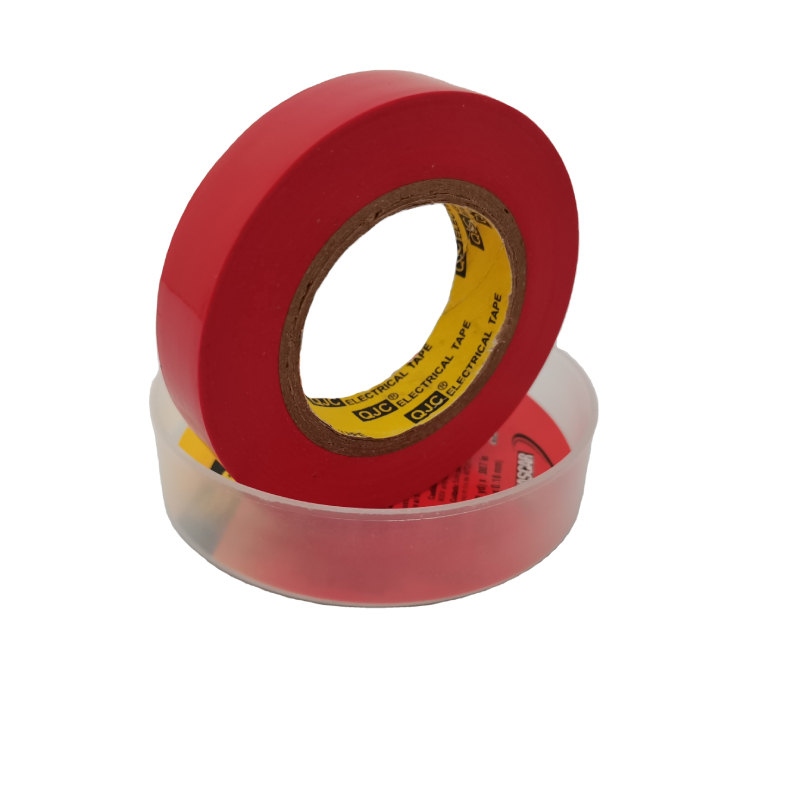

Rubber splicing tape is a versatile tool in the realms of electrical work, automotive repair, and DIY home projects. As someone who has spent years navigating the complexities of various applications involving splicing tapes, I’ve come to appreciate the crucial role this humble product plays in ensuring safety, durability, and efficiency.

Equally important is the residential application of rubber splicing tape, which demonstrates its adaptability and efficacy in everyday scenarios. Homeowners with a penchant for DIY repairs find it an invaluable resource for managing minor wiring projects or repairs. Its user-friendliness stems from its non-tacky nature prior to application, allowing easy manipulation around complex or intricate wiring tasks. Furthermore, for home improvements requiring a more refined finish, rubber splicing tape’s smooth surface once bonded provides a professional appearance that does not veer into unsightliness. Credible sources such as electrical safety organizations and industry experts continually advocate for the use of high-quality rubber splicing tape to ensure compliance with safety and performance standards. The tape’s inherent ability to prevent electrical shock hazards by providing a stable insulating layer is a testament to its trustworthiness. During my career, collaborating with electrical engineers and safety inspectors, the recurrent emphasis on using quality-approved tapes has been paramount in project execution. An unexplored aspect often overlooked is the role of rubber splicing tape in preserving sustainability in demanding environments. Many manufacturers recognize the need to produce tapes that are not only effective but also environmentally friendly. These tapes are often developed with materials that withstand the test of time, reducing the need for frequent replacements and thereby limiting waste. Industry leaders in electrical solutions encourage the adoption of such innovations, aligning with broader environmental goals and responsible consumption ideals. Conclusively, the authority and reliability of rubber splicing tape lie in its multifaceted applications across industries requiring electrical insulation and protection. Years of hands-on experience, fortified by expert consensus, highlight its security provisions, adaptability in varying conditions, and capacity to effectively serve diverse roles—from industrial applications to household repairs. As the narrative around safety and efficiency continues to evolve, rubber splicing tape remains a steadfast component in achieving impeccable standards in electrical solutions.

Equally important is the residential application of rubber splicing tape, which demonstrates its adaptability and efficacy in everyday scenarios. Homeowners with a penchant for DIY repairs find it an invaluable resource for managing minor wiring projects or repairs. Its user-friendliness stems from its non-tacky nature prior to application, allowing easy manipulation around complex or intricate wiring tasks. Furthermore, for home improvements requiring a more refined finish, rubber splicing tape’s smooth surface once bonded provides a professional appearance that does not veer into unsightliness. Credible sources such as electrical safety organizations and industry experts continually advocate for the use of high-quality rubber splicing tape to ensure compliance with safety and performance standards. The tape’s inherent ability to prevent electrical shock hazards by providing a stable insulating layer is a testament to its trustworthiness. During my career, collaborating with electrical engineers and safety inspectors, the recurrent emphasis on using quality-approved tapes has been paramount in project execution. An unexplored aspect often overlooked is the role of rubber splicing tape in preserving sustainability in demanding environments. Many manufacturers recognize the need to produce tapes that are not only effective but also environmentally friendly. These tapes are often developed with materials that withstand the test of time, reducing the need for frequent replacements and thereby limiting waste. Industry leaders in electrical solutions encourage the adoption of such innovations, aligning with broader environmental goals and responsible consumption ideals. Conclusively, the authority and reliability of rubber splicing tape lie in its multifaceted applications across industries requiring electrical insulation and protection. Years of hands-on experience, fortified by expert consensus, highlight its security provisions, adaptability in varying conditions, and capacity to effectively serve diverse roles—from industrial applications to household repairs. As the narrative around safety and efficiency continues to evolve, rubber splicing tape remains a steadfast component in achieving impeccable standards in electrical solutions.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025