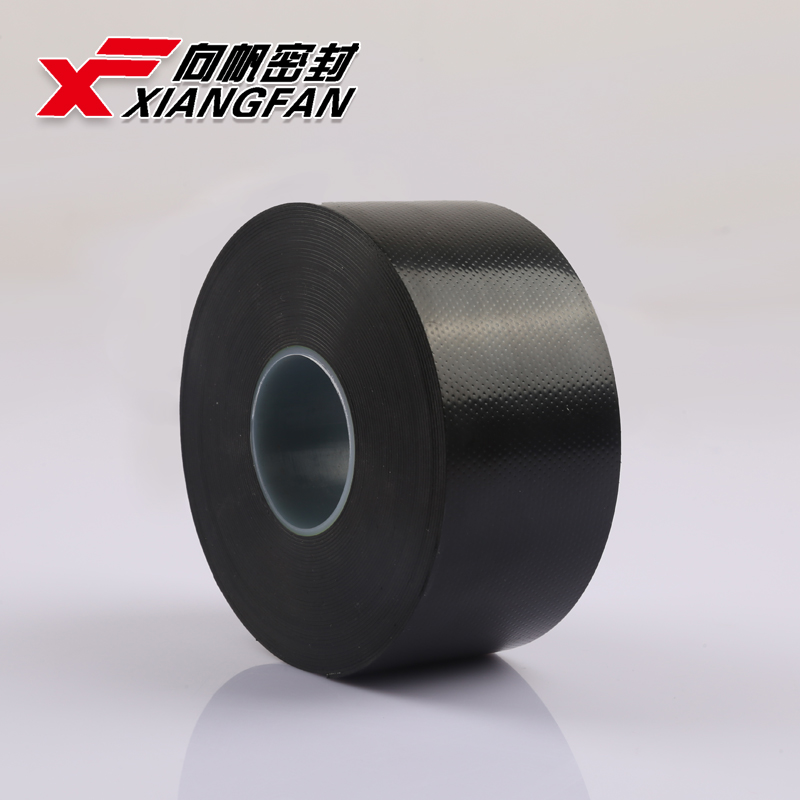

waterproof butyl rubber tape

Back to list

Jan . 21, 2025 02:07

Waterproof butyl rubber tape has revolutionized both industrial and domestic sectors with its impressive sealing capabilities. Many users often find themselves wondering, what sets this miracle tape apart from other weatherproofing options? When delving into the mechanics and applications of butyl rubber tape, its effectiveness is rooted in its unique properties, coupled with expert endorsements and real-world usage scenarios that scream reliability and versatility.

Trust in waterproof butyl rubber tape is further strengthened by endorsements from authoritative institutions in construction and repair. Certifications from these bodies not only authenticate its material quality but also endorse its environmental compliance standards, assuring users of its safety and sustainability characteristics. But it’s not just about corporate endorsements. Trust is also built through peer-to-peer recommendations. Communities, including DIY enthusiasts and customers, openly discuss their long-term use cases and successes with waterproof butyl rubber tape. In forums, the tape is often hailed as a 'savior' in emergency repairs, and people recount their surprise and satisfaction at how effectively it managed leaks and prevented further water damage in time-sensitive scenarios. Regarding installation, simplicity is another aspect that cannot be overlooked. No need for specialized equipment or extensive preparation; users appreciate its peel-and-stick application. This user-friendliness lowers the barrier for entry, making it accessible even to those who lack professional training in repairs or construction work. In conclusion, the adage seeing is believing holds when considering the effectiveness and reliability of waterproof butyl rubber tape. It is this amalgamation of expert validation, authentic user experiences, and credible manufacturing integrity that establishes it as a trustworthy product in the market. As technology and needs evolve, so does the ambition for even more advanced sealing solutions, yet the foundational strength of waterproof butyl rubber tape remains a constant, ensuring continued high esteem and demand in years to come.

Trust in waterproof butyl rubber tape is further strengthened by endorsements from authoritative institutions in construction and repair. Certifications from these bodies not only authenticate its material quality but also endorse its environmental compliance standards, assuring users of its safety and sustainability characteristics. But it’s not just about corporate endorsements. Trust is also built through peer-to-peer recommendations. Communities, including DIY enthusiasts and customers, openly discuss their long-term use cases and successes with waterproof butyl rubber tape. In forums, the tape is often hailed as a 'savior' in emergency repairs, and people recount their surprise and satisfaction at how effectively it managed leaks and prevented further water damage in time-sensitive scenarios. Regarding installation, simplicity is another aspect that cannot be overlooked. No need for specialized equipment or extensive preparation; users appreciate its peel-and-stick application. This user-friendliness lowers the barrier for entry, making it accessible even to those who lack professional training in repairs or construction work. In conclusion, the adage seeing is believing holds when considering the effectiveness and reliability of waterproof butyl rubber tape. It is this amalgamation of expert validation, authentic user experiences, and credible manufacturing integrity that establishes it as a trustworthy product in the market. As technology and needs evolve, so does the ambition for even more advanced sealing solutions, yet the foundational strength of waterproof butyl rubber tape remains a constant, ensuring continued high esteem and demand in years to come.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025