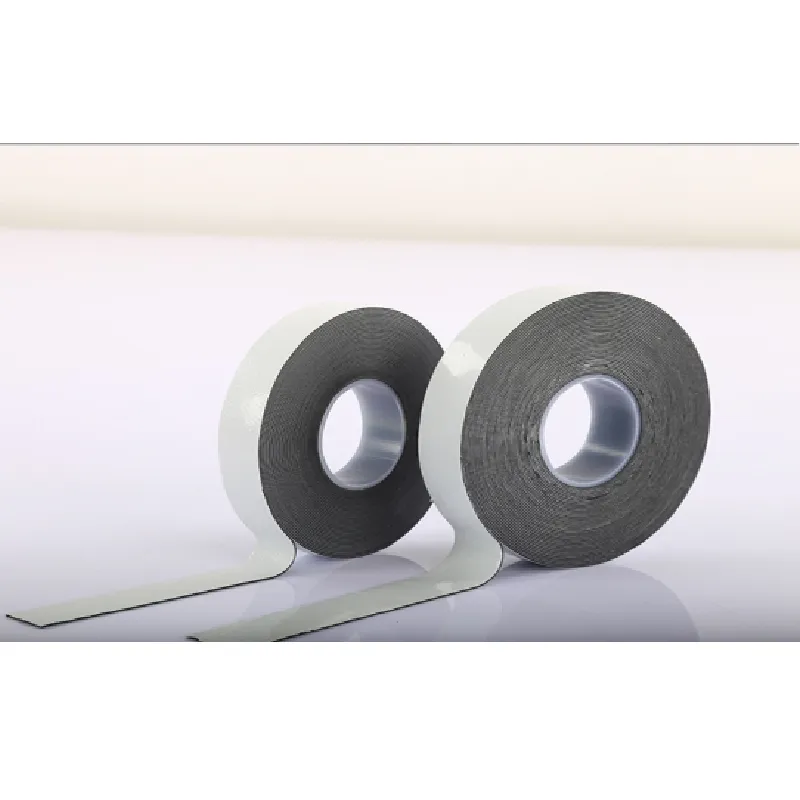

self amalgamating tape heat resistant

Back to list

Feb . 13, 2025 09:30

Self-amalgamating tape, particularly the heat resistant variant, is a remarkable innovation in the world of electrical insulation and repair. This type of tape is designed to fuse with itself without any need for additional adhesive, creating a seamless barrier to protect against heat and other environmental factors. Its unique composition makes it a vital tool for both professionals and DIY enthusiasts seeking effective solutions for sealing and insulation needs.

Authoritativeness is significant in recommending the best uses for self-amalgamating heat resistant tape. Industry experts, backed by years of field research and development, endorse specific brands and compositions based on rigorous testing. The tape's resistance to weathering, UV degradation, and ozone is consistently highlighted in technical bulletins and application guides. Manufacturers with ISO certifications further bolster the tape’s credibility, ensuring it meets international safety and quality standards. This documentation empowers users to make informed decisions based on empirical evidence rather than mere marketing claims. Trustworthiness is paramount among users who emphasize the tape’s ability to form a watertight and airtight seal. Customer testimonials and case studies serve as compelling evidence of its reliability. Field tests often demonstrate that the tape can withstand pressures and forces without compromising its structure, a fact reiterated by professionals in sectors ranging from marine engineering to telecommunications. Moreover, independent reviews frequently note the absence of residue left upon removal, a critical factor for applications requiring maintenance or part replacement. In conclusion, while self-amalgamating tape is a product born from scientific advancement, its real-world applications and user testimonials cement its status as a trustworthy, expert-endorsed solution. Its ability to deliver robust and reliable insulation under demanding conditions speaks volumes of its value. As industries increasingly seek efficient and durable materials, self-amalgamating heat resistant tape stands out as not just a tool, but an essential asset for achieving optimal performance and safety.

Authoritativeness is significant in recommending the best uses for self-amalgamating heat resistant tape. Industry experts, backed by years of field research and development, endorse specific brands and compositions based on rigorous testing. The tape's resistance to weathering, UV degradation, and ozone is consistently highlighted in technical bulletins and application guides. Manufacturers with ISO certifications further bolster the tape’s credibility, ensuring it meets international safety and quality standards. This documentation empowers users to make informed decisions based on empirical evidence rather than mere marketing claims. Trustworthiness is paramount among users who emphasize the tape’s ability to form a watertight and airtight seal. Customer testimonials and case studies serve as compelling evidence of its reliability. Field tests often demonstrate that the tape can withstand pressures and forces without compromising its structure, a fact reiterated by professionals in sectors ranging from marine engineering to telecommunications. Moreover, independent reviews frequently note the absence of residue left upon removal, a critical factor for applications requiring maintenance or part replacement. In conclusion, while self-amalgamating tape is a product born from scientific advancement, its real-world applications and user testimonials cement its status as a trustworthy, expert-endorsed solution. Its ability to deliver robust and reliable insulation under demanding conditions speaks volumes of its value. As industries increasingly seek efficient and durable materials, self-amalgamating heat resistant tape stands out as not just a tool, but an essential asset for achieving optimal performance and safety.

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025