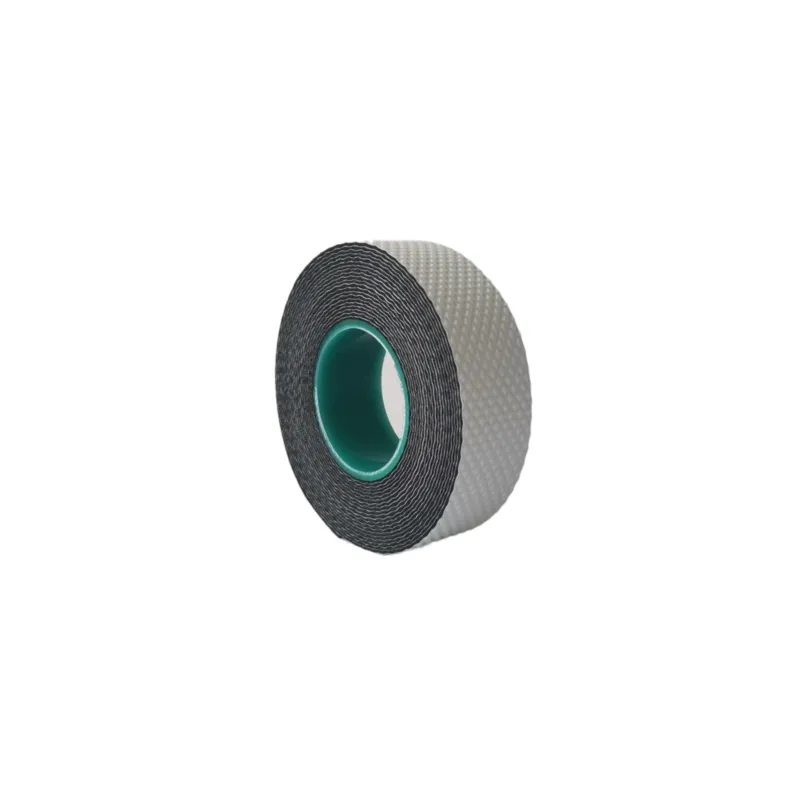

weld tape self amalgamating

Back to list

Jan . 14, 2025 09:51

In the realm of sealing and insulating solutions, weld tape self amalgamating emerges as a superior choice with its unique ability to create a seamless, watertight bond. This innovative product stands out due to its self-fusing nature, offering unmatched efficiency and reliability across various applications. To truly appreciate its capabilities, it’s vital to delve into its practical use, guided by real-world experiences and expert insights.

Trustworthiness is further reinforced through documented performance metrics and user testimonials, which consistently praise the tape’s durability and ease of use. Several case studies emphasize its role in emergency repairs, where its quick application and reliable performance have mitigated potential damages, thereby saving time and costs. Manufacturers of weld tape self amalgamating concentrate on meeting stringent quality standards to ensure consistent performance. This commitment to quality is evident in the rigorous testing phases each roll undergoes before reaching the consumer. As technology evolves, these products continue to incorporate advanced materials and manufacturing techniques, enhancing their practical application and reliability. To optimize the use of weld tape self amalgamating, consumers are advised to invest in high-quality products from reputable brands, ensuring long-term efficacy. An understanding of the specific project requirements and an assessment of the environmental conditions further guide the selection process, aligning product characteristics with practical needs. In conclusion, weld tape self amalgamating stands as a testament to innovation in sealing technologies. Its ability to deliver a reliable, long-lasting solution underlines its growing popularity among professionals and DIY enthusiasts alike. For anyone seeking a robust solution in sealing or insulating, understanding the nuanced applications of this tape through expert lenses assures its potential to meet and exceed expectations.

Trustworthiness is further reinforced through documented performance metrics and user testimonials, which consistently praise the tape’s durability and ease of use. Several case studies emphasize its role in emergency repairs, where its quick application and reliable performance have mitigated potential damages, thereby saving time and costs. Manufacturers of weld tape self amalgamating concentrate on meeting stringent quality standards to ensure consistent performance. This commitment to quality is evident in the rigorous testing phases each roll undergoes before reaching the consumer. As technology evolves, these products continue to incorporate advanced materials and manufacturing techniques, enhancing their practical application and reliability. To optimize the use of weld tape self amalgamating, consumers are advised to invest in high-quality products from reputable brands, ensuring long-term efficacy. An understanding of the specific project requirements and an assessment of the environmental conditions further guide the selection process, aligning product characteristics with practical needs. In conclusion, weld tape self amalgamating stands as a testament to innovation in sealing technologies. Its ability to deliver a reliable, long-lasting solution underlines its growing popularity among professionals and DIY enthusiasts alike. For anyone seeking a robust solution in sealing or insulating, understanding the nuanced applications of this tape through expert lenses assures its potential to meet and exceed expectations.

Next:

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025