As electrical safety and regulatory standards continue to rise, selecting fire retardant electrical tape becomes imperative for reliable insulation and accident prevention. Discover cutting-edge technology, technical data, and expert trends, featuring premium solutions from JULU COUNTRY XIANGFAN SEALS FACTORY.

Contact JULU COUNTRY XIANGFAN SEALS FACTORY

Email: tony_qin@qjcxfmfj.com

Address: OFFICE BUILDING OF MANAGEMENT COMMITTEE OF SHIZISHAN HIGH-TECH ZONE, TONGLING, ANHUI, CHINA

Industry Overview: The Demand for Fire Retardant Electrical Tape

The global electrical insulation landscape is experiencing rapid technological advancement. Key factors include stricter fire safety codes, increasing complexity of automotive/population infrastructure, and demand for reliability from electronics to construction. Fire retardant electrical tape is essential—not only for “tape electrical insulation” requirements, but also for reliable “tape for construction,” automotive harnessing, and general electrical insulation tape duties.

In recent industry symposia, safety authorities highlight that the use of certified fire retardant electrical tape can reduce electrical fire incidents by over 30% (Source: IEEE Conference Reports).

Technical Data Table: Fire Retardant Electrical Tape Key Parameters

| Parameter | Typical Value | Measurement Standard | Application Significance |

|---|---|---|---|

| Base Material | PVC (Polyvinyl Chloride) | ASTM D1000 | Provides robust insulation |

| Adhesive Type | Pressure-sensitive (Rubber-based or Acrylic) | UL 510 | Ensures firm grip on wires |

| Flame Retardancy | V-0 or VTM-0 | UL 94 | Prevents flame propagation |

| Operating Temperature | -20°C to +105°C | IEC 60454-3-1 | Wide range, suitable for automotive/electronics |

| Dielectric Strength | ≥ 40 kV/mm | IEC 60243 | Prevents breakdown voltage |

| Tape Thickness | 0.13 – 0.19 mm | ASTM D1000 | Balances flexibility and durability |

| RoHS Compliance | Yes | 2011/65/EU | Environmentally safe |

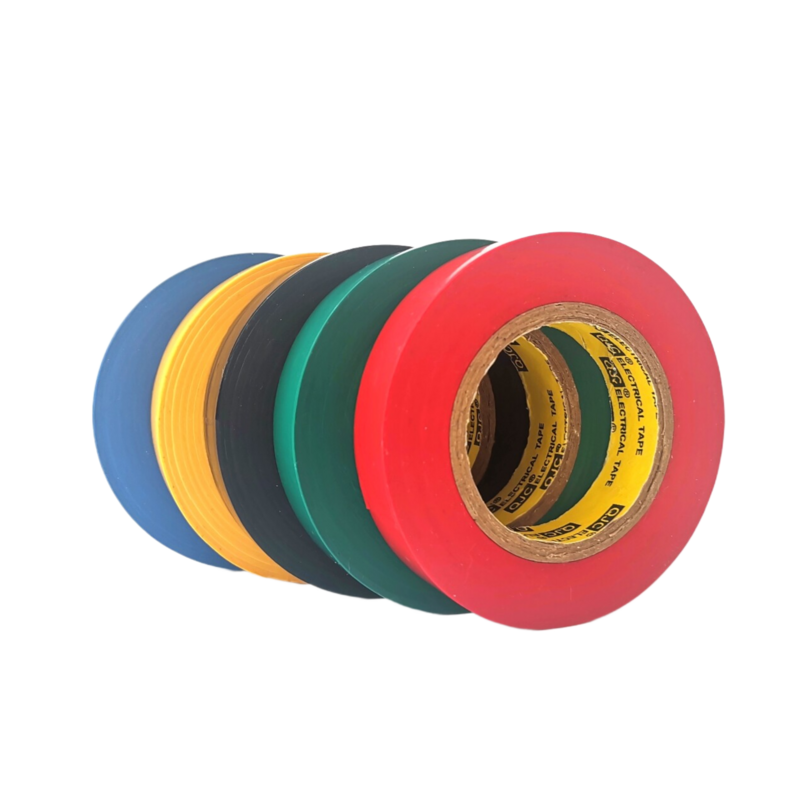

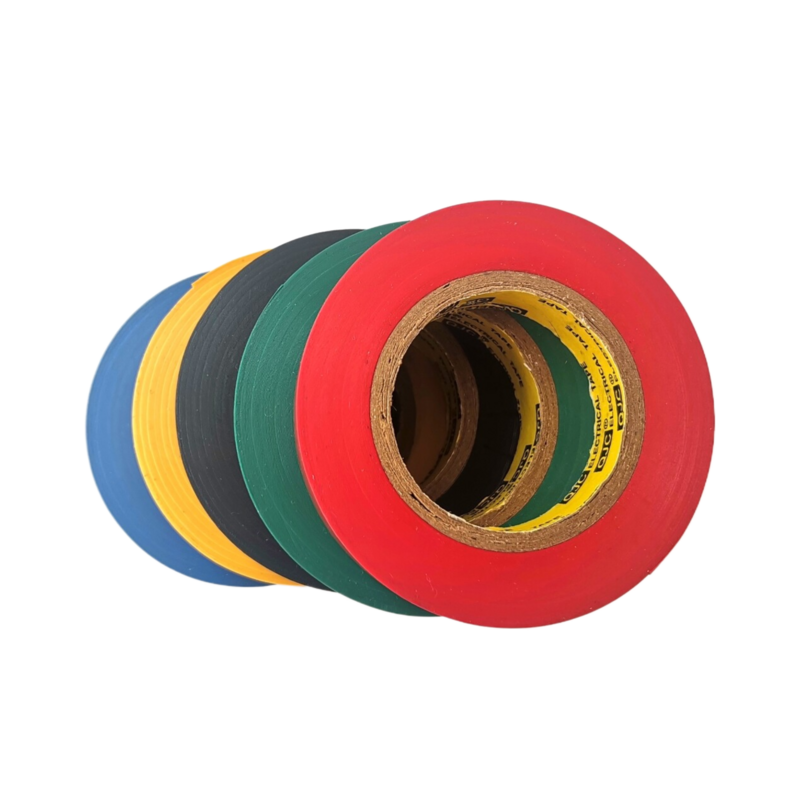

| Colors Available | Black, Red, White, Green, Blue, Yellow, Grey | Industry Standard | Visual coding & safety |

Featured Product: Flame Retardant Automotive Wire Harness PVC Tape

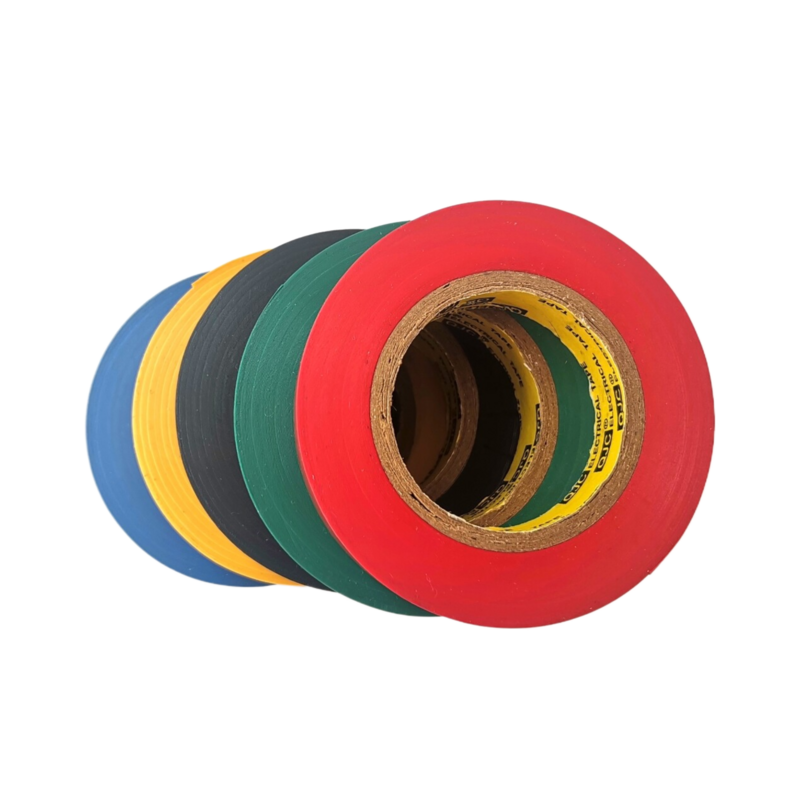

Color: Black, Red, White, Green, Blue, Yellow, Grey

Specialty: XF-FR110 Flame Retardant Automotive Wire Harness PVC Tape utilizes a PVC film plasticized with DOP, coated with high-performance pressure-sensitive adhesive. Characterized by superior insulation, voltage resistance, flame retardancy, cold resistance, and environmental conformity (ROHS).

Explore more technical info: Fire Retardant Electrical Tape product page.

Technical Data Visualization: XF-FR Series vs. Industry Standard

Application Scenarios: From Automotive to Construction

- Automotive wire harness assembly: XF-FR110 and related grades ensure wire cluster safety even under high thermal loads.

- Building & construction tape: For fire-rated insulation, sealing cable runs, panel gaps, and floor raceways.

- General electrical maintenance: For “tape electrical insulation” in residential, commercial, and industrial circuits.

- Color coding & marking: Various colors aid quick identification, crucial in panel boards and control systems.

- Electronics and appliance manufacturing: Used during and after assembly for protection from short circuits and heat.

- Public transport & aviation: Compliance with international standards for flame retardancy.

Professional FAQ: Understanding Fire Retardant Electrical Tape

Features & Advantages of JULU COUNTRY XIANGFAN SEALS FACTORY’s XF-FR Series

- Certified fire retardant electrical tape with reliable flame-retardant capability (V-0 class).

- High voltage and dielectric protection: suitable for both automotive and industrial electrical insulation tape applications.

- Excellent conformability, elasticity, and easy tear property—reducing application errors in the field.

- Available in multiple colors; “tape for construction” and coding applications.

- Strong adhesive strength, resisting peel and flagging, even in cold or humid conditions.

- Compliance with ROHS, REACH, UL, and IEC standards.

- Proven track record in OEM automotive harnessing, global construction sites, and electronics assembly.

Industry Trends & Future Outlook for Fire Retardant Tape

Industry forums and international standards bodies note increasing migration from traditional tapes to specialized fire retardant electrical tape (see ECMag Best Practices). Market growth is fueled by increasing electrification, automotive electronics, smart building demand, tighter insurance/fire codes, and expanding robotics and IoT industries.

Next-gen tapes will feature biodegradable or halogen-free chemistries, even greater dielectric strength and operational temperature range, and enhanced user-ease for harsh setting installations.

- IEEE Xplore: "Fire Resistant Tape Innovation in Electrical Applications" (2019)

- ECMag: Electrical Contractor Magazine – Best Practices in Electrical Tape

- Materials Performance Journal: Tapes for High-Performance Cable Insulation (2023)

- Building & Construction Forum: Electrical Tape Fire Ratings Guide

- Official Standards: UL-510, IEC Standards

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025