Flex Tape Waterproof - Ultimate Waterproof Tape for Instant Sealing Solutions

Back to list

Jul . 25, 2025 04:01

Enterprise: JULU COUNTRY XIANGFAN SEALS FACTORY |

Website: https://www.qiangdatape.com

Tel: +86-15902204128 Mobile: +86-13932918280

Email: tony_qin@qjcxfmfj.com

Address: OFFICE BUILDING OF MANAGEMENT COMMITTEE OF SHIZISHAN HIGH-TECH ZONE, TONGLING, ANHUI, CHINA

Tel: +86-15902204128 Mobile: +86-13932918280

Email: tony_qin@qjcxfmfj.com

Address: OFFICE BUILDING OF MANAGEMENT COMMITTEE OF SHIZISHAN HIGH-TECH ZONE, TONGLING, ANHUI, CHINA

In the evolving world of sealing technologies, flex tape waterproof solutions, including flex tape waterproof tape, waterproof rubber tape, and waterproof rubber sealing strip, have become vital across construction, automotive, marine, and household sectors. At the forefront, JULU COUNTRY XIANGFAN SEALS FACTORY presents the innovative Rubber waterproof composite tape (flex tape waterproof), which demonstrates superior self-adhesion, temperature resistance, and sealing performance.

Industry Trends: Growth & Innovations in Flex Tape Waterproof Solutions

The demand for high-performance flex tape waterproof and specialized variants such as flex tape white is surging, driven by strict infrastructure standards and the proliferation of DIY repair needs. According to Statista, the global market for waterproof tapes is expected to register a CAGR of over 6% through 2027, with synthetic rubber-based tapes occupying the largest market segment due to their flexibility and broad temperature tolerance.

Key industry forums (LinkedIn Market Insights) highlight technological progress in formulations that improve UV resistance, long-term elasticity, and environmental safety. The shift toward greener, halogen-free compounds and demand for tape customizations reflect 2024’s strong innovation momentum.

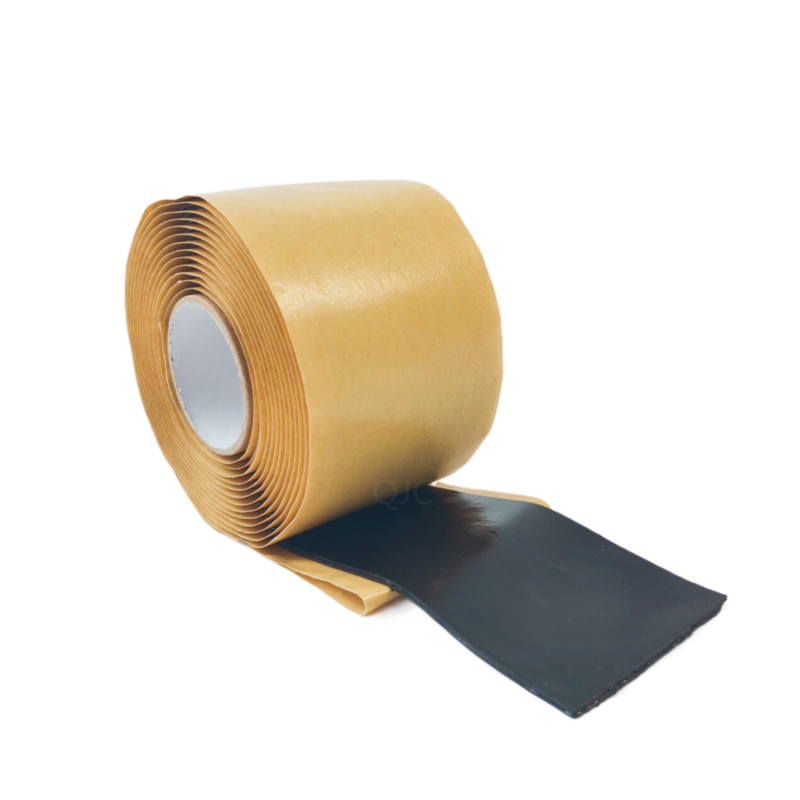

About the Product: Rubber Waterproof Composite Tape (XF-S18)

Product: Rubber Waterproof Composite Tape

Model: XF-S18

Color: Black

Overview: XF-S18 Rubber waterproof composite tape is an advanced self-adhesive, highly shape-conforming waterproof sealing tape with excellent electrical insulation. Its core is a premium, aging-resistant synthetic rubber, incorporating a robust adhesive system and notable temperature resistance.

Product page: https://www.qiangdatape.com/rubber-waterproof-composite-tape.html

Model: XF-S18

Color: Black

Overview: XF-S18 Rubber waterproof composite tape is an advanced self-adhesive, highly shape-conforming waterproof sealing tape with excellent electrical insulation. Its core is a premium, aging-resistant synthetic rubber, incorporating a robust adhesive system and notable temperature resistance.

Product page: https://www.qiangdatape.com/rubber-waterproof-composite-tape.html

Key Parameters Table: Flex Tape Waterproof Comparison

| Parameter | Flex Tape Waterproof | Waterproof Rubber Tape | Rubber Waterproof Composite Tape (XF-S18) | Common Uses |

|---|---|---|---|---|

| Adhesive Base | Synthetic Rubber | Butyl/Synthetic Rubber | Synthetic Rubber | Sealing, Repair |

| Thickness (mm) | 0.5 - 1.5 | 0.65 - 2.0 | 0.80 ± 0.10 | Waterproofing, Isolation |

| Temperature Range (°C) | -40 ~ +120 | -35 ~ +100 | -25 ~ +105 | Outdoor/Indoor |

| Electrical Resistance | High | Moderate | High (≥1012 Ωcm) | Wire/Joint Insulation |

| Color Options | Black, White, Clear | Varied | Black | Decorative, Discreet Repairs |

| Elongation (%) | ≥ 600 | 200 - 400 | ≥ 500 | Twisting Seals, Flexible Surfaces |

| Waterproof Level | IPX7-IPX8 | IPX5-IPX7 | IPX7 | Submersion, Leak Stop |

Technical Data Visualizations: ECharts Interactive Charts

Application Scenarios: From DIY to Industrial Solutions

Flex tape waterproof technology supports a spectrum of applications. In home maintenance, it instantly seals burst pipes, cracks, and leaking rooftops — even under submersion. Rubbery flexibility and high conformability make flex tape waterproof tape ideal for irregular, curved, or moist surfaces where conventional tapes fail. Within automotive and marine domains, it serves as a vital emergency repair solution for hoses, bodywork, windows, and hatches.

The Rubber waterproof composite tape is widely used in:

- HVAC duct sealing, wire harness insulation, cable joint waterproofing

- Roofing, flashing, gutter repairs

- Outdoor electrical enclosures

- Marine & RV roof and hatch sealing

- Industrial pipeline and tank leak sealing

- Concrete expansion joint protection

Technological Developments: Enhanced Waterproofing by XF-S18

Based on recent patents (CN109781564A), recent advances in waterproof rubber tape compositions ensure extreme weather and UV resistance, while specialized adhesive layers effectively prevent migration and oil exudation even at high heat. The XF-S18 specifically utilizes a synthetic rubber formula enhanced with anti-aging and anti-ozone agents for long lifespan—key to outdoor, industrial, and marine installations where reliability and safety are paramount.

According to studies in Journal of Adhesion Science and Technology, rubber-based self-fusing tapes demonstrate higher energy dissipation and viscoelastic recovery, outperforming acrylic-based waterproof tapes in cyclic temperature and elongation tests. This echoes the reported feedback from global forums (Reddit DIY): rubber tapes maintain consistent seals and adhesion through freeze-thaw cycles where others fail.

Expert FAQ: All About Flex Tape Waterproof and Composite Tape Technology

Q1: What is the core material used in flex tape waterproof solutions?

A1: High-quality synthetic rubber, often blended with butyl for enhanced flexibility and weather resistance, is standard. The compounded materials provide outstanding waterproofing and mechanical stability (Tape University).

Q2: Which technical parameter best defines tape longevity?

A2: Aging resistance (usually measured by accelerated UV/weathering tests) and adhesion retention at temperature extremes are primary indicators of product lifespan.

Q3: What are the standard installation practices for waterproof rubber sealing strip and tapes?

A3: Surfaces must be clean and dry. When installing XF-S18 or similar tapes, apply with 10–20% stretch and overlap generously. For critical sealing, roll or press the tape surface to remove air pockets and maximize contact area.

Q4: How does the color variant (e.g., flex tape white) affect performance?

A4: Color affects solar heat absorption and visibility. Flex tape white reduces thermal buildup under sun exposure, suitable for rooftops and visible locations, while black offers superior UV resistance.

Q5: What certifications are typical for flex tape waterproof products?

A5: Leading tapes achieve RoHS, REACH, UL electrical insulation grades, and IPX7 or higher waterproofing benchmarks. XF-S18 also targets SGS testing compliance.

Q6: Are there minimum thickness or specific width recommendations?

A6: For waterproof joint sealing, a minimum 0.8mm thickness and ≥25mm width is suggested for lasting adhesion—XF-S18 is precisely designed with these standards in mind.

Q7: Can Rubber waterproof composite tape be used for electrical insulation?

A7: Yes, its high volume resistivity (>1012 Ωcm) and dielectric strength ensure safe insulation in cable joins and splitters, outperforming most PVC or fiber tapes under wet conditions.

Why Choose JULU COUNTRY XIANGFAN SEALS FACTORY?

JULU COUNTRY XIANGFAN SEALS FACTORY, with industry-leading expertise in flex tape waterproof solutions, adheres strictly to international quality systems and deploys state-of-the-art materials in all development stages. The factory’s R&D leverages the latest research findings, actively participating in global trade expositions and professional forums.

- Strong manufacturing capacity: Custom roll sizes, colors, and performance engineering.

- Technological authority: In-house laboratory and ISO-compliant testing.

- Research-driven reliability: Product enhancements in self-healing, fire-retardance, and submersion sealing.

- Global reach: Export to 57+ countries, serving industry, trade, and retail.

For consulting, bulk order, or technical inquiries about flex tape waterproof or Rubber waterproof composite tape, contact our expert team via tony_qin@qjcxfmfj.com or call +86-15902204128 / +86-13932918280.

Conclusion

As waterproofing demands diversify in both industrial and DIY sectors, the excellence of flex tape waterproof—specifically through high-end innovations like the Rubber waterproof composite tape from JULU COUNTRY XIANGFAN SEALS FACTORY—sets a new performance and reliability standard. Embracing progressive technologies, rigorous testing, and comprehensive aftersales support, the company stands as a reliable partner for waterproofing excellence.

References & Further Reading:

[1] Journal of Adhesion Science and Technology

[2] Tape University: Waterproof Tape Guide

[3] Statista: Adhesive Tapes Market

[4] Reddit DIY Forum

[5] Google Patents: Waterproof Tape CN109781564A

[6] LinkedIn: Trends in Adhesive Tapes Market

[1] Journal of Adhesion Science and Technology

[2] Tape University: Waterproof Tape Guide

[3] Statista: Adhesive Tapes Market

[4] Reddit DIY Forum

[5] Google Patents: Waterproof Tape CN109781564A

[6] LinkedIn: Trends in Adhesive Tapes Market

Latest news

-

XIANGFAN Rubber Tape-Ultimate Solutions for All Your Insulation NeedsNewsJun.24,2025

-

XIANGFAN Rubber Tape-Protection for Industrial and Residential ApplicationsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Superior Safety and Sealing for Demanding EnvironmentsNewsJun.24,2025

-

XIANGFAN Rubber Tape: Reliable Solutions for Every Electrical ChallengeNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Powering Reliability Across IndustriesNewsJun.24,2025

-

XIANGFAN Electrical & Industrial Tape: Excellence in Every ApplicationNewsJun.24,2025