Understanding High-Performance Medium Voltage Fusion Tape

In the demanding realm of electrical infrastructure, the integrity of insulation is paramount. Modern electrical systems, particularly those operating at medium voltage, require advanced materials that can withstand rigorous operational conditions while ensuring long-term reliability and safety. This necessitates the use of specialized insulating products like medium voltage fusion tape. This self-amalgamating tape provides superior electrical insulation, moisture sealing, and environmental protection, making it an indispensable component in critical applications across diverse industries. This article delves into the technical aspects, applications, and strategic advantages of this essential material for B2B decision-makers and engineering professionals.

Industry Trends and Market Dynamics

The global market for electrical insulation materials is experiencing robust growth, driven by increasing investments in power transmission and distribution infrastructure, the proliferation of renewable energy projects, and the ongoing modernization of industrial facilities. A key trend is the demand for materials that offer enhanced performance characteristics, such as higher dielectric strength, broader temperature resistance, and superior environmental sealing capabilities. As grid reliability becomes increasingly critical, the adoption of advanced insulating solutions like medium voltage fusion tape is accelerating.

Innovations in polymer science are leading to the development of tapes with improved self-amalgamating properties, making installation faster and more reliable, even in challenging field conditions. Furthermore, the push for sustainable practices is encouraging manufacturers to develop products with longer service lives and reduced environmental footprints. The integration of smart grid technologies also places a premium on insulation materials that can ensure uninterrupted power flow and protect sensitive electronic components from environmental ingress. The broader category of rubber tape electrical products continues to evolve, with fusion tapes representing the pinnacle of performance for demanding electrical applications.

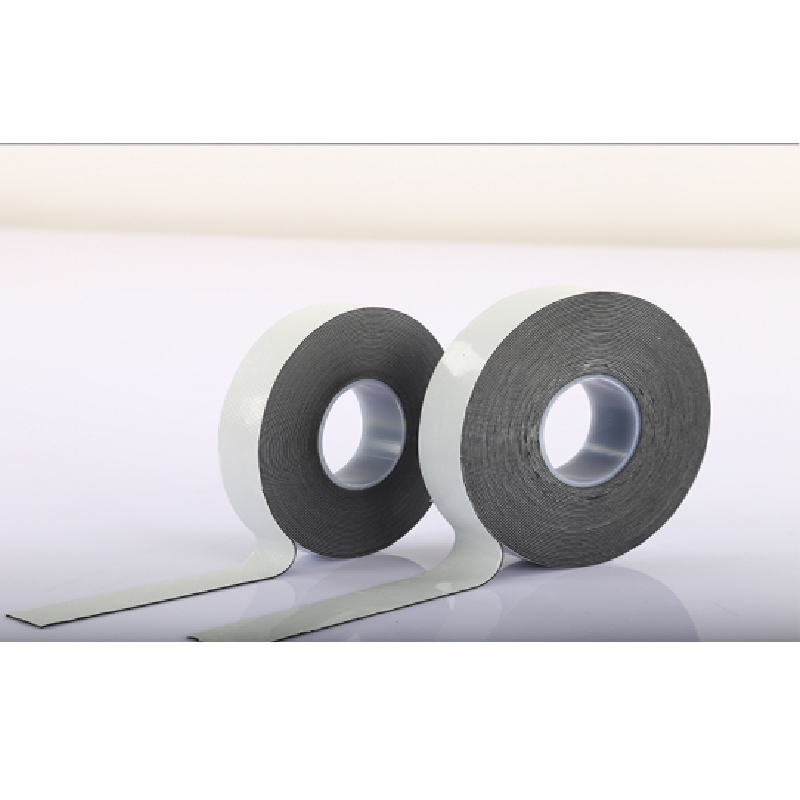

Image 1: Advanced electrical insulation with fusion tape.

The Manufacturing Process of Medium Voltage Fusion Tape

The production of high-quality medium voltage fusion tape involves a meticulous process to ensure optimal material properties and consistent performance. The core material typically consists of an ethylene propylene rubber (EPR) base, compounded with specialized cross-linking agents, tackifiers, and fillers to achieve its unique self-amalgamating and insulating characteristics.

Process Flow:

- Material Compounding: Raw EPR polymer is mixed with precise proportions of additives, including vulcanizing agents, antioxidants, flame retardants, and processing aids, in a high-shear mixer. This stage is crucial for achieving the desired electrical, mechanical, and thermal properties.

- Calendering/Extrusion: The compounded material is then processed through a calendering machine or an extruder. Calendering involves pressing the material into thin, uniform sheets between heated rollers. Extrusion forces the material through a die to form a continuous strip of specified thickness. This ensures dimensional accuracy and consistency.

- Curing/Vulcanization: The formed sheet or strip undergoes a controlled curing process (vulcanization) where the rubber polymer chains are cross-linked. This step significantly enhances the tape's strength, elasticity, heat resistance, and long-term stability. The degree of cure is carefully monitored.

- Release Liner Application: A specialized release liner, typically made of polyethylene, is applied to one side of the tape. This liner prevents the tape from amalgamating prematurely during storage and allows for easy unwinding during application.

- Slitting and Winding: The cured and lined material is then precisely slit into the desired widths (e.g., 19mm, 25mm, 50mm) and wound onto rolls with specific lengths. Automated slitting and winding ensure clean edges and consistent roll tension.

- Quality Control and Packaging: Each batch undergoes rigorous testing to meet stringent quality standards. This includes electrical tests (dielectric strength, volume resistivity), mechanical tests (tensile strength, elongation, self-amalgamation rate), and environmental tests (ozone resistance, UV stability). Products are then packaged for shipment, often in moisture-resistant container111s.

Testing Standards and Service Life: Manufacturers adhere to international standards such as ISO 9001 for quality management, and product-specific standards like ASTM D4388, IEC 60454, or various national standards (e.g., BS EN 60454-3-19) for electrical insulating tapes. These standards ensure that the tape meets specified performance criteria for dielectric strength, temperature ratings, and environmental durability. A well-manufactured medium voltage fusion tape typically offers a service life exceeding 20 years when properly applied and maintained, significantly contributing to the longevity of electrical assets.

Target Industries and Advantages: This tape is critical in industries such as petrochemical, metallurgy, power generation and distribution (utilities), water supply & drainage, mining, and telecommunications. Its advantages include superior energy saving through minimal power loss at connection points, excellent corrosion resistance due to a robust moisture seal, and enhanced safety by preventing electrical breakdowns.

Image 2: Precision manufacturing ensures tape integrity.

Technical Specifications and Performance Parameters

Selecting the appropriate medium voltage fusion tape requires a thorough understanding of its technical specifications. These parameters define the tape's suitability for specific voltage levels, environmental conditions, and mechanical stresses. Key performance indicators include dielectric strength, operating temperature range, tensile strength, and self-amalgamation rate.

Product Specification Table: Medium Voltage Fusion Tape (Typical Values)

| ਪੈਰਾਮੀਟਰ | Typical Value | Description / Standard |

|---|---|---|

| Material Composition | Ethylene Propylene Rubber (EPR) | High-performance synthetic rubber compound. |

| ਡਾਈਇਲੈਕਟ੍ਰਿਕ ਤਾਕਤ | ≥ 25 kV/mm (635 V/mil) | Maximum voltage insulation capability (ASTM D4388). |

| ਵਾਲੀਅਮ ਪ੍ਰਤੀਰੋਧਕਤਾ | > 10^14 Ohm·cm | Measure of electrical resistance; indicates excellent insulation. |

| Operating Temperature | -40°C to +90°C | Safe continuous operating range. |

| Emergency Overload Temp. | Up to 130°C | Short-term resistance to elevated temperatures. |

| ਲਚੀਲਾਪਨ | ≥ 1.5 MPa (217 psi) | Resistance to breaking under tension (ASTM D4388). |

| Elongation at Break | ≥ 500% | Flexibility and ability to stretch before rupture (ASTM D4388). |

| Self-Amalgamation Rate | ≥ 95% (after 24h at RT) | Degree to which tape fuses to itself; crucial for a monolithic seal. |

| Ozone Resistance | Excellent | Ability to withstand ozone attack without cracking. |

| ਪਾਣੀ ਸਮਾਈ | Very Low | Ensures excellent moisture sealing properties. |

These specifications ensure that the tape performs reliably under the demanding electrical and environmental conditions typical of medium voltage applications. The high dielectric strength prevents electrical breakdown, while robust mechanical properties ensure durability and resistance to wear.

Image 3: Demonstrating the flexibility of fusion tape.

Critical Application Scenarios

The versatility and robust performance of medium voltage fusion tape make it suitable for a wide array of mission-critical applications where reliable electrical insulation and environmental sealing are non-negotiable.

- Cable Jointing and Terminations: This is arguably the most common application. The tape is used to insulate, seal, and protect cable splices and terminations in both underground and overhead installations. Its self-amalgamating nature creates a void-free, waterproof seal that resists moisture ingress, preventing electrical faults. It is frequently employed in medium voltage systems ranging from 1 kV to 35 kV.

- Busbar Insulation: In switchgear and control panels, busbars are often insulated with fusion tape to prevent flashovers and improve personnel safety. The tape conforms tightly to irregular shapes, providing uniform insulation.

- Repair of Damaged Cable Jackets: For minor damage to outer cable jackets or insulation, fusion tape provides a quick, effective, and durable repair, restoring the cable's protective layer and preventing further degradation from environmental factors.

- Moisture Sealing and Corrosion Protection: Beyond electrical insulation, the tape forms an excellent moisture barrier around connections, conduit entries, and pipe joints, effectively preventing corrosion in harsh industrial or marine environments. This is particularly valuable in petrochemical and water treatment facilities.

- Phasing and Color Coding: While primarily for insulation, some variants can be used for color-coding in electrical systems, though typically other tapes are preferred for this specific function.

- General Utility Applications: From insulating overhead service connections to underground secondary network connections, fusion tape is a staple for utility companies ensuring grid reliability.

Image 4: Cable jointing in a demanding environment.

Technical Advantages and Benefits

The distinct characteristics of medium voltage fusion tape offer several compelling advantages over conventional electrical tapes, positioning it as a superior choice for critical applications.

- Self-Amalgamating Properties: Upon application with tension, the layers of the tape fuse into a solid, homogeneous, void-free mass. This creates a seamless, permanent seal that is impenetrable to moisture, air, and other contaminants, unlike non-fusing tapes that rely on adhesive bonds that can degrade over time. This property ensures a high-integrity seal for decades.

- Exceptional Electrical Insulation: With a high dielectric strength, fusion tape effectively insulates against electrical breakdown, preventing short circuits and ensuring the safe operation of medium voltage equipment. Its consistent thickness and uniform composition contribute to reliable insulation performance.

- Superior Environmental Resistance: The EPR-based composition provides excellent resistance to UV radiation, ozone, aggressive chemicals, and extreme temperatures. This makes it ideal for both indoor and outdoor applications, including harsh environments found in mining, marine, and chemical processing plants.

- Flexibility and Conformability: The tape's inherent elasticity allows it to conform tightly to irregular shapes and surfaces without wrinkling or creating air pockets, which are common points of failure in other insulating methods. This ensures a complete and uniform seal, even on complex geometries.

- Corrosion and Water Protection: By forming a watertight and airtight seal, the tape prevents moisture and corrosive agents from reaching sensitive electrical connections, thereby extending the lifespan of cables and components and reducing maintenance costs.

- Ease of Application: Despite its high technical performance, the tape is relatively easy to apply without specialized tools, making field installations efficient and less labor-intensive. Its clean removal of the liner further streamlines the process.

- Long-Term Stability: Once amalgamated, the tape maintains its electrical and physical properties over a broad temperature range and long periods, contributing to the overall reliability and longevity of the electrical system.

Image 5: High-performance insulation for critical connections.

Vendor Comparison and Selection Criteria

When sourcing medium voltage fusion tape, B2B buyers face a variety of options. A discerning selection process is crucial to ensure product quality, reliability, and value. Here's a comparative overview of key vendor attributes:

Key Vendor Comparison Criteria:

| Criterion | High-Quality Vendor (e.g., Qiangda) | Typical Commodity Vendor |

|---|---|---|

| Certifications & Standards | ISO 9001, ASTM D4388, IEC 60454, RoHS/REACH compliant | Limited or self-declared standards, fewer international certifications |

| Material Purity & Consistency | Uses virgin EPR, strict compounding, uniform thickness | May use recycled materials, inconsistent blend, variable thickness |

| Dielectric Strength (kV/mm) | ≥ 25 kV/mm, verified by third-party tests | Lower values, less stringent testing |

| Self-Amalgamation Rate | ≥ 95%, forms a truly monolithic structure | Lower rates, potential for voids and delamination |

| Environmental Resistance | Excellent UV, Ozone, Chemical resistance (tested) | Degrades faster in outdoor/harsh conditions |

| Technical Support & Expertise | Dedicated engineering support, application guidance | Minimal or generic support, limited technical depth |

| Customization Options | Available (width, length, formulation for specific needs) | Limited to standard off-the-shelf products |

Authored by a company with over 20 years of experience in electrical insulation solutions, such as Qiangda Tape, clients benefit from proven expertise and a commitment to quality. Our products undergo rigorous testing and meet global industry standards, including partnerships with major utility providers and industrial enterprises worldwide.

Image 6: Quality control for electrical insulation products.

Customized Solutions for Unique Requirements

Recognizing that standard products may not always perfectly align with highly specialized project demands, leading manufacturers of medium voltage fusion tape offer customized solutions. This flexibility is particularly valuable for large-scale industrial projects, unique environmental conditions, or specific regulatory compliance needs.

- Tailored Dimensions: While common widths (e.g., 25mm, 50mm) and lengths are standard, customized widths and thicknesses can be produced to optimize material usage, reduce installation time, or meet specific application envelopes. This can range from narrow tapes for intricate repairs to wider tapes for larger cable joints.

- Specific Performance Requirements: For projects demanding enhanced flame retardancy, higher temperature resistance, or improved chemical compatibility, the tape's formulation can be adjusted. This might involve incorporating different additives or modifying the EPR blend.

- Private Labeling and Packaging: Manufacturers can provide products under a client's own brand, complete with custom packaging, labeling, and barcoding. This is ideal for distributors, integrators, and large-scale contractors.

- Bespoke R&D Capabilities: Advanced vendors invest in research and development to address novel challenges. This means working directly with clients to engineer entirely new tape solutions for groundbreaking applications or to overcome persistent issues.

Companies like Qiangda Tape, with over two decades of material science expertise, possess the engineering capabilities to develop bespoke solutions, ensuring that the final product precisely matches the operational needs and technical specifications of any demanding project. This collaborative approach ensures optimal performance and cost-efficiency.

Image 7: Tailored solutions for specific project needs.

Application Case Studies

Real-world applications demonstrate the tangible benefits of utilizing high-quality medium voltage fusion tape in diverse and challenging environments.

Case Study 1: Substation Modernization Project

An electrical utility company undertook a major modernization of an aging substation operating at 15kV. The project required thousands of cable joints and terminations to be insulated and sealed, often in confined spaces with varying ambient temperatures. Traditional heat-shrink insulation methods were proving too time-consuming and prone to installation errors. By standardizing on a high-performance medium voltage fusion tape, the utility achieved a 30% reduction in installation time per joint due to the tape's ease of application and quick self-amalgamation. Post-installation testing confirmed superior dielectric integrity and moisture resistance, contributing to a projected 25% increase in the operational lifespan of the cable network within the substation and significantly reducing future maintenance costs. Customer feedback highlighted the ease of use and the reliability of the permanent seal.

Case Study 2: Industrial Petrochemical Plant Expansion

A petrochemical facility required robust electrical insulation and corrosion protection for control cables and power lines (up to 6.6kV) in areas exposed to aggressive chemicals and high humidity. Standard electrical tapes failed prematurely due to chemical degradation and moisture ingress. After consultation, a specialized formulation of medium voltage fusion tape with enhanced chemical resistance was adopted. This tape was used for both primary insulation and as an outer protective jacket for cable repairs and new installations. After three years of continuous operation, inspections revealed no signs of degradation, moisture ingress, or electrical faults, even in the most exposed areas. This prevented costly downtime and reaffirmed the long-term reliability of the fusion tape solution in extreme conditions. The plant manager praised the tape's ability to maintain integrity where other materials failed.

Image 8: Field application in a challenging industrial setting.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust with B2B clients involves transparency in product information, logistical capabilities, and after-sales support.

Frequently Asked Questions (FAQ)

-

Q: What is the optimal storage condition for rubber tape electrical fusion tapes?

A: For best results, store in a cool, dry place away from direct sunlight and sources of heat, ideally between 10°C and 30°C (50°F and 86°F). Ensure the product remains in its original packaging until ready for use to prevent premature amalgamation or contamination. -

Q: Can this tape be applied in cold weather?

A: While medium voltage fusion tape is designed for a broad temperature range, application in extremely cold conditions (below 0°C/32°F) may reduce its initial tack and amalgamation rate. Pre-warming the tape to room temperature is recommended for optimal performance in cold environments. -

Q: Is a primer required before applying the tape?

A: Typically, no primer is required for most applications. The self-amalgamating properties of the tape ensure excellent adhesion to itself and most common cable insulation materials. Ensure surfaces are clean and dry before application. -

Q: How many layers of tape should be applied for proper insulation?

A: The number of layers depends on the voltage level and the application. For most medium voltage applications (up to 35kV), a minimum of two to three half-lapped layers is recommended to build sufficient dielectric strength and a robust environmental seal. Consult specific product data sheets or application guides for precise recommendations.

Lead Time and Fulfillment

Qiangda Tape maintains efficient manufacturing processes and a robust supply chain to ensure timely delivery. Standard orders for medium voltage fusion tape typically have a lead time of 7-14 business days, depending on order volume and specific product configurations. For custom orders or large-scale project requirements, lead times will be communicated upon inquiry, with a dedicated project manager assigned to ensure seamless coordination from production to delivery. We offer flexible shipping options, including expedited services for urgent requirements.

Warranty Commitments

All Qiangda Tape products are backed by a comprehensive warranty against manufacturing defects and material failures when used under recommended conditions. Our medium voltage fusion tape is guaranteed to meet or exceed published technical specifications for a period of 12 months from the date of purchase. We stand by the quality and performance of our products, reflecting our confidence in our stringent quality control processes and material selection.

Customer Support and After-Sales Service

Our commitment to our clients extends beyond the sale. Qiangda Tape provides dedicated technical support, offering expert guidance on product selection, application techniques, and troubleshooting. Our team of experienced engineers is available via phone, email, or online consultation to address any technical queries. For complex projects, on-site technical assistance can be arranged. We also offer comprehensive training materials and application videos to ensure optimal product utilization and customer satisfaction.

Image 9: Reliable support for our valued partners.

Conclusion

In the intricate world of B2B electrical infrastructure, the choice of insulating materials can significantly impact operational reliability, safety, and long-term cost-efficiency. Medium voltage fusion tape stands out as a high-performance solution, offering unparalleled electrical insulation, environmental protection, and ease of application. By understanding its technical specifications, manufacturing processes, and diverse application scenarios, engineers and procurement specialists can make informed decisions that safeguard critical assets and enhance system integrity. Partnering with experienced manufacturers like Qiangda Tape ensures access to products that not only meet but often exceed industry standards, backed by robust support and a commitment to innovation.

References

- IEC 60454-3-19: Pressure-sensitive adhesive tapes for electrical purposes - Part 3: Specifications for individual materials - Sheet 19: Requirements for self-amalgamating EPR based tapes. International Electrotechnical Commission.

- ASTM D4388: Standard Specification for Nonmetallic Semi-Conducting and Insulating Rubber Tapes for Electrical Cables. ASTM International.

- IEEE Std 100-2000: The Authoritative Dictionary of IEEE Standards Terms. Institute of Electrical and Electronics Engineers.

- NEMA WC 74/ICEA S-93-639: 5-46 kV Shielded Power Cable for Use in the Transmission and Distribution of Electric Energy. National Electrical Manufacturers Association.

- Electric Power Research Institute (EPRI) Publications on Cable Systems and Insulation Materials.

-

Medium Voltage Fusion Tape | Self-Fusing Electrical Insulationਖ਼ਬਰਾਂAug.28,2025

-

Butyl Rubber Tape for Ventilation Pipesਖ਼ਬਰਾਂAug.22,2025

-

Flex Tape Waterproof for Underground Cablesਖ਼ਬਰਾਂAug.22,2025

-

Flame Retardant Tapes for Circuit Insulationਖ਼ਬਰਾਂAug.22,2025

-

Foam Tape Door Seal With 19mm Widthਖ਼ਬਰਾਂAug.22,2025

-

Self Annealing Tape Honoring Engineering Careਖ਼ਬਰਾਂAug.22,2025